Overview

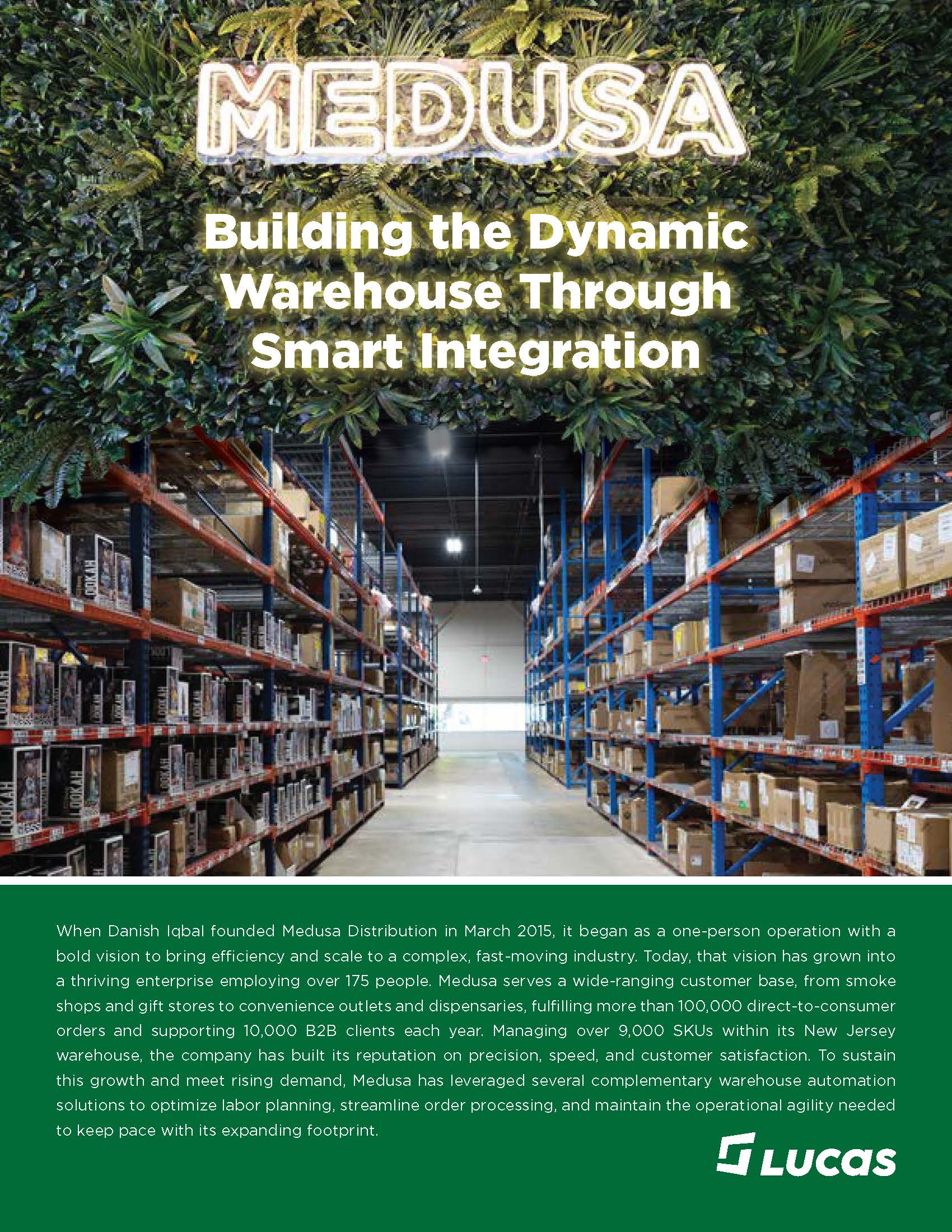

When Danish Iqbal founded Medusa Distribution in March 2015, it began as a one-person operation with a bold vision to bring efficiency and scale to a complex, fast-moving industry. Today, that vision has grown into a thriving enterprise employing over 175 people. Medusa serves a wide-ranging customer base, from smoke shops and gift stores to convenience outlets and dispensaries, fulfilling more than 100,000 direct-to-consumer orders and supporting 10,000 B2B clients each year. Managing over 9,000 SKUs within its New Jersey warehouse, the company has built its reputation on precision, speed, and customer satisfaction. To sustain this growth and meet rising demand, Medusa has leveraged several complementary warehouse automation solutions to optimize labor planning, streamline order processing, and maintain the operational agility needed to keep pace with its expanding footprint.

Rigid Processes, Rising Costs: Why Change Became Essential

Medusa Distribution faced mounting challenges as it sought to scale operations and meet customer expectations for speed and accuracy. The company’s rapid growth exposed inefficiencies in its paper-based picking process and dependence on “tribal knowledge,” meaning experienced team members who carried critical know-how in their heads rather than in standardized systems. Order accuracy was inconsistent, and location-based inventory tracking was virtually nonexistent, leading to frequent delays and fulfillment errors.

These challenges were amplified when handling large wholesale orders with thousands of SKUs and units, particularly when late-day orders demanded same-day shipping. Compounding these issues was rigid automation that had multi-tiered rules for splitting and boxing orders—often based on outdated or inaccurate logic—that resulted in wasted space and excessive “air” in shipped boxes.

As order complexity increased, resembling that of pharmacy replenishment operations where speed and precision are paramount, Medusa’s manual processes simply couldn’t keep up. The business needed a scalable solution that would streamline order processing, support faster onboarding of new employees, and enable efficient, accurate picking and packing at scale. The push for automation became a critical step toward reducing dependency on tribal knowledge, boosting order accuracy, and creating the flexibility needed to sustain growth in a fast-moving distribution environment.

“We love partnering with companies like Lucas, Perseuss, and Deposco that actually care about the people doing the work. Their technology doesn’t just optimize operations, it makes the day-to-day experience better for our employees.”

Solution

Medusa Distribution took its first major step toward dynamic warehousing by implementing Deposco’s Warehouse Management System (WMS). This move replaced the company’s legacy paper-based picking with a location-based inventory system powered by RF scanners, giving teams better visibility and data of product movement. The WMS streamlined order management and introduced smarter packing logic aligned with carrier restrictions, laying the groundwork for more agile fulfillment. However, as order complexity and volume continued to grow, it became clear that Medusa needed additional intelligent systems to optimize packing, reduce waste, and increase flexibility to become more dynamic.

To address these challenges, Medusa turned to Lucas Systems for warehouse execution software that included voice-directed picking and dynamic workflow optimization capabilities that simplified and streamlined picking operations across the warehouse, combined with Perseuss.

Integration Partners

Lucas: Warehouse Execution System

Deposco: Warehouse Management System

Perseuss: Cartonization and Shipping System

Perseuss provides AI-powered cartonization for parcels and pallets to reduce shipping costs, maximize space and streamline fulfillment. To explain how it all works, Perseuss pulls order data directly from Deposco and communicates with Jennifer, the brains, orchestration engine and voice of the Lucas Systems to determine optimal box sizes, required stickers, and labeling details. This integration ensures that each order is packed efficiently, with minimal air in boxes, and meets carrier and customer requirements automatically. Once orders are packed, Perseuss triggers label generation and final shipment processing through Deposco, creating a seamless, closed-loop system from pick to ship.

By introducing direct-to-carton picking, Lucas eliminated an entire handling step—allowing associates to pick directly into the final shipping container rather than staging or re-boxing. This change significantly reduced labor needed, improved efficiency, and increased throughput.

“We have the adaptability now to pick the same order across multiple carts and multiple pickers. In the past, we weren’t able to do that, so if a large order comes in late in the day, we’re actually able to get that order out the door with multiple people picking it.”

Beyond that, Lucas’s Dynamic Work Optimization feature continuously analyzes pick paths in real time, ensuring the most efficient route for each associate. This resulted in a productivity increase from 100 to 140 pick faces per hour, measurable labor savings, and smoother onboarding for new employees through Jennifer’s guided, language-flexible voice-directed workflows.

The Results: Efficiency, Accuracy, and Cost Savings

- 40% Increase in productivity (100 to 140 pick faces per hour)

- 99.99+% Accuracy

- 30-35% Reduction in cost per unit

The ease of integration and combined power of Deposco, Perseuss, and Lucas Systems has transformed Medusa’s operations from the ground up. The company now reports a 99.99+% order accuracy rate, verified through internal audits and customer feedback. Productivity has surged thanks to dynamic optimization and direct-to-carton picking, while intelligent packing logic has led to seven-figure annual savings and a 30-35% reduction in cost per unit.

Medusa’s warehouse now runs with precision and flexibility, supporting multi-language workflows, real-time productivity tracking, and continuous improvement initiatives that keep performance at peak levels. What once required deep tribal knowledge and manual coordination is now a finely tuned, data-driven operation—one that scales effortlessly to meet the growing demands of its customers.