How to build automated pick and pack operations that deliver 99.9% accuracy and same-day fulfillment

Your 3PL pick and pack operations determine whether customers become loyal advocates or abandon your business after a single disappointing experience. Top 3PLs maintain error rates below 0.02% through automation and systematic processes, which translates to fewer returns, lower costs, and happier customers.

The Stakes: Over half of U.S. retailers now offer same-day shipping, a move that can dramatically increase sales conversion rates. The third-party logistics market is projected to reach $1.4 trillion globally in 2025. Organizations that master automated 3PL pick and pack capture market share and can charge higher prices (and get what they’re worth). Those clinging to manual processes will remain anchored in cost constraints and lose customers to more capable competitors.

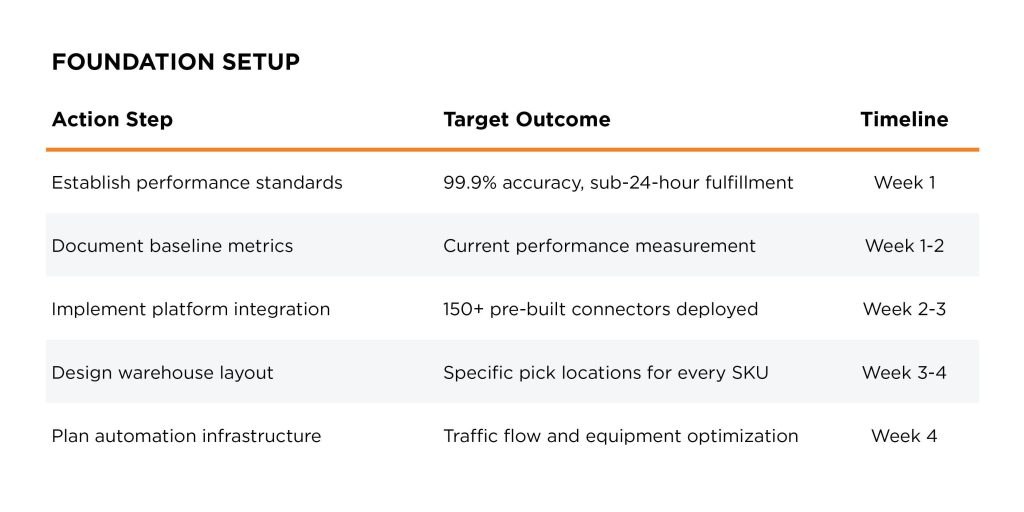

Action steps for foundational setup

Most 3PLs struggle with performance measurement because they lack integrated systems that capture real-time data across all operational touchpoints. Robust 3PL WMS software automatically tracks and reports on these critical metrics, eliminating manual data collection and providing the accuracy needed for continuous improvement.

Most 3PLs struggle with performance measurement because they lack integrated systems that capture real-time data across all operational touchpoints. Robust 3PL WMS software automatically tracks and reports on these critical metrics, eliminating manual data collection and providing the accuracy needed for continuous improvement.

Performance standards that drive results

Your 3PL pick and pack operations must achieve 99.9% outbound order accuracy as the minimum acceptable standard, with inventory accuracy around 99.5%. These benchmarks represent the performance levels necessary to compete effectively in today’s demanding marketplace. Companies achieving these standards see measurable improvements in customer retention and operational profitability.

✔ Calculate the true cost of errors in your operation before implementing any changes. Mispicks require correction, which can lead to cascading costs through returns processing, increased customer service time, and a negative impact on customer lifetime value. When a single shipping mistake can cost 10x the order value, prevention becomes a strategic imperative rather than an operational nicety.

✔ Document your current performance baseline across key metrics, including order accuracy rates, pick time per order, processing time from order receipt to shipment, and customer complaint frequency. This baseline provides the foundation for measuring improvement as you implement enhanced 3PL pick and pack procedures. Without this baseline, you cannot accurately measure ROI or justify automation investments.

Order management (OMS) drives +99% order accuracy and transforms CX.

Technology infrastructure that enables growth

Your 3PL pick and pack success depends on seamless platform integration that connects every aspect of your operation. Modern 3PL WMS systems require API connections to all ecommerce platforms, with 150+ pre-built integrations for major marketplaces like Amazon, Shopify, WooCommerce, and more, significantly reducing integration time and costs compared to custom development.

✔ Real-time inventory synchronization with ERP systems like NetSuite, SAP, and Microsoft Dynamics prevents overselling and maintains customer trust across all sales channels. This integration enables automatic order validation, which verifies customer information, payment status, and shipping requirements before processing begins, thereby preventing downstream complications that can create customer service issues.

✔ Complementary integrations, such as EDI for enterprise clients with automated batch processing, efficiently handle high-volume orders. Meanwhile, mobile device scanning with lot tracking, serial numbers, and expiration dates ensures compliance with regulatory requirements. This is especially beneficial in use cases like cold chain food traceability.

✔ Multi-carrier parcel integration with rate shopping across all the major and regional carriers optimizes shipping costs automatically, while Transportation Management System connectivity enables freight optimization for larger shipments.

Save 2% to 20% on shipping costs in just a few clicks. Advanced rate shopping tools enable you to shop rates across many carriers in one WMS interface quickly.

Warehouse layout optimization for automated pick and pack

Design your warehouse layout with specific pick locations for every SKU to prevent productivity-killing searches while enabling predictable performance standards. Travel time can easily account for 50% or more of order picking hours, making strategic placement one of the highest-impact improvements you can implement immediately.

✔ Implement SKU segregation strategies to prevent the mixing of different products in storage locations. While this may use more space, the productivity gains from eliminating search time far exceed storage cost penalties. Position high-volume items near packing areas based on velocity analysis, while seasonal products can be located in less accessible areas during off-peak periods.

✔ Create logical product zones that enable efficient automated navigation and task allocation while designing pathways that accommodate both human workers and automated systems safely. Ensure that automated systems can access all storage locations without operational conflicts, and designate spaces for automated equipment servicing that do not disrupt operations.

Learn 25 Warehouse Organization Tips to Maximize Efficiency

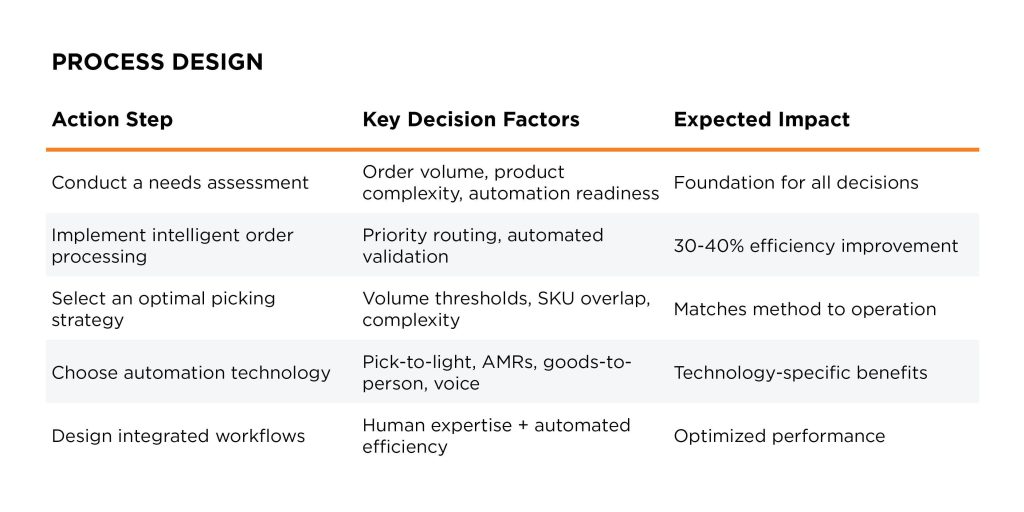

Action steps for process design

The biggest mistake 3PLs make is treating all orders the same way, regardless of complexity, value, or client requirements. Advanced 3PL WMS software platforms use intelligent algorithms to automatically route orders through optimal workflows, ensuring each shipment receives the appropriate level of attention while maximizing overall throughput.

The biggest mistake 3PLs make is treating all orders the same way, regardless of complexity, value, or client requirements. Advanced 3PL WMS software platforms use intelligent algorithms to automatically route orders through optimal workflows, ensuring each shipment receives the appropriate level of attention while maximizing overall throughput.

Comprehensive needs assessment before automation

Before implementing any automated 3PL pick and pack technology, conduct a thorough evaluation of your current operations to identify the most impactful improvement opportunities. Analyze your order volume and seasonal fluctuation patterns to understand capacity requirements during peak periods, which often exceed 300% of baseline throughput.

✔ Evaluate product variety and complexity, including size, weight, fragility, and special handling requirements. Different 3PL automation technologies excel with varying types of product—pick-to-light systems work best for small, uniform items, while AMRs handle diverse product catalogs more effectively.

✔ Assess your existing workforce capabilities and technology infrastructure to determine your readiness for automation. Consider questions like: What percentage of your orders can be fulfilled in under 60 minutes? Which product categories generate the highest error rates? How does seasonal demand impact your current labor requirements? What are your biggest operational bottlenecks during peak periods?

Stop eating cost increases, start charging what you’re worth.

Order processing excellence framework

Start with intelligent order processing that prioritizes shipments based on service commitments, customer value, and operational efficiency. Leading WMS systems make strategic decisions about fulfillment that optimize both customer satisfaction and operational costs.

✔ Create order batching logic that strategically groups orders. Batch picking typically improves productivity by 30-40% compared to piece picking for operations handling more than 100 orders per day. Your system should automatically analyze order volume, SKU overlap, and operational capacity to determine optimal batching strategies.

✔ Single-order picking works best for operations with fewer than 50 orders daily or when handling high-value, customized products that require individual attention. For large warehouses with diverse product categories, a WMS system like Deposco supports zone picking strategies that divide facilities into specialized areas where pickers develop expertise in specific product types, improving both speed and accuracy.

✔ Implement wave picking for sophisticated operations that require coordination of labor, equipment, and shipping operations. Group orders into scheduled waves aligned with shipping cutoffs and carrier pickups, maximizing operational efficiency while meeting service commitments.

Automated picking technology options

Pick-to-Light Systems transform picking accuracy by using LED displays to guide workers to exact item locations with visual cues. This technology significantly reduces picking errors while increasing productivity by eliminating paperwork and the need for handheld device consultation. These systems work best for high-volume operations with consistent SKU velocity and relatively uniform product sizes.

Check out Pick-to-Light in action with our customer Altitude Sports:

Autonomous Mobile Robots (AMRs) represent the cutting edge of automated pick and pack technology, navigating warehouses using LiDAR, cameras, and advanced sensors. These intelligent systems provide dynamic task allocation based on real-time order priorities while working safely alongside human workers through collision avoidance technology. AMRs offer exceptional scalability, adapting to fluctuating order volumes without requiring additional labor.

Goods-to-Person Automated Systems eliminate worker travel time entirely by bringing inventory directly to picking stations. This approach maximizes space utilization through vertical storage optimization while reducing labor requirements and increasing picking accuracy. These systems prove ideal for operations with diverse SKU catalogs and varying order sizes.

Voice-Directed Picking enables hands-free operation through audio instructions and confirmations, allowing workers to focus on picking tasks without needing to consult screens or paperwork. This technology integrates seamlessly with existing WMS systems, enabling real-time task coordination and proving particularly effective for batch picking and zone-based operations.

What can you do with MHE warehouse solutions? More importantly, what do you need to get there? Here’s a framework for seamless integration and immediate value.

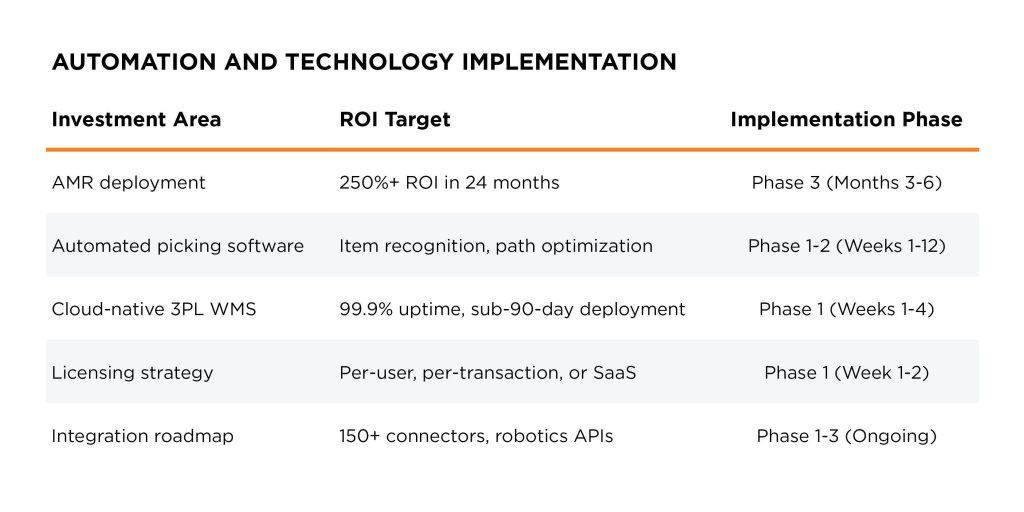

ROI targets for implementing automation and tech

Many 3PLs either over-invest in automation (more than they need without the right tech foundation) or resist technology adoption until they’re forced to catch up with competitors. A modern 3PL WMS serves as the central nervous system, coordinating all warehouse activities and providing the data foundation necessary to make informed automation investments with measurable ROI.

Many 3PLs either over-invest in automation (more than they need without the right tech foundation) or resist technology adoption until they’re forced to catch up with competitors. A modern 3PL WMS serves as the central nervous system, coordinating all warehouse activities and providing the data foundation necessary to make informed automation investments with measurable ROI.

Automated pick and pack investment strategy

Forrester research shows that automation can provide a 79% ROI and save companies millions in cost savings and improved efficiency with payback within 18 months of upfront investment. As a result, automation is an attractive investment for growing businesses. However, successful automation requires strategic selection and implementation.

✔ Start with mobile scanning and basic WMS automation in weeks 1-4, progress to automated picking routes and intelligent batching in weeks 5-8, then implement AMRs and advanced pick and pack automation in months 3-6.

✔ AI-powered WMS platforms offer real-time optimization and predictive analytics for automated workflows, while barcode scanning automation with mobile devices enables the capture of lot and serial numbers and automated validation throughout the process.

Technology integration and software features

Modern automated picking software must incorporate comprehensive item recognition technology, utilizing barcode scanning, RFID tracking, and image recognition, for accurate product identification. Intelligent task management automatically allocates picking tasks based on order priority, item location, and worker availability. At the same time, path planning optimization calculates the most efficient routes considering item size, order priority, and travel time minimization.

✔ Real-time error handling capabilities detect missing items and damaged products, implementing automatic corrective actions before errors reach customers.

✔ Safety and collision avoidance features protect workers through built-in protocols that prevent accidents with automated equipment.

✔ The software architecture must support scalability, allowing for adaptation to growth and integration of additional functionalities as your business expands.

✔ Real-time analytics continuously generate performance reports, track metrics, and identify improvement opportunities.

WMS capabilities for 3PL success

✔ Select cloud-native 3PL WMS platforms with proven sub-90-day implementation track records and 99.9% uptime guarantees. These systems must provide real-time inventory tracking across all locations with 99%+ accuracy, automated route optimization for pickers with AI-powered task assignment, and integration with 150+ native platforms, including marketplaces and ERP systems.

✔ Multi-client inventory segregation with client-specific workflow configuration enables 3PLs to serve diverse customers efficiently.

✔ Automated billing capture for storage fees, pick-and-pack charges, and value-added services ensures accurate invoicing.

✔ Cloud architecture with elastic scaling during demand spikes automatically handles peak periods, and robotics API connectivity enables seamless integration with AMRs and automated storage systems.

✔ Consider WMS license models carefully: per-user models have limited scalability with break-even at 50+ concurrent users, per-transaction models scale with volume and break-even at 10,000+ monthly transactions. In contrast, SaaS subscription models offer unlimited scaling with predictable budgeting and immediate value realization.

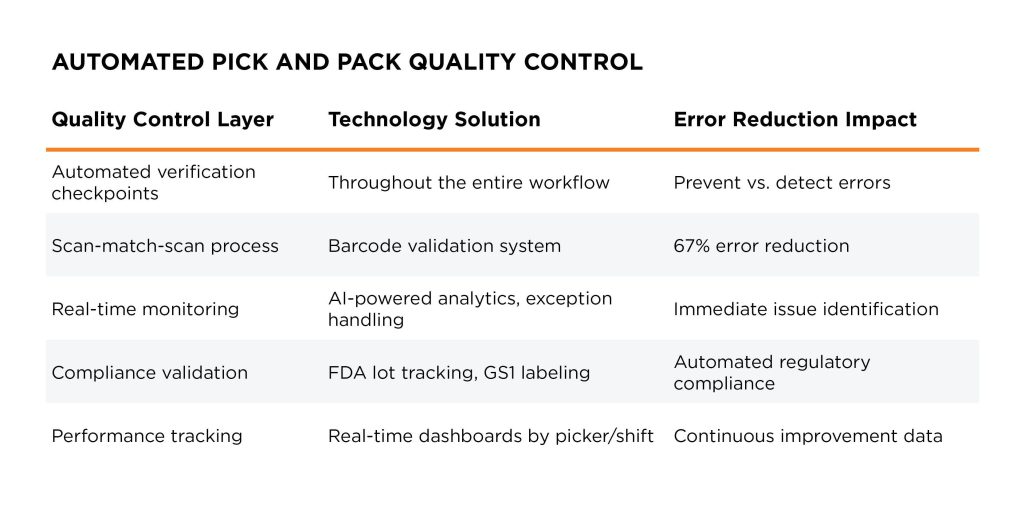

Ensuring quality control in automated pick and pack

The difference between good and great 3PLs lies in their ability to prevent errors rather than just catch them after they occur. Quality-focused 3PL WMS platforms embed automated verification checkpoints throughout the workflow, making it nearly impossible for incorrect items to reach customers while maintaining operational speed.

The difference between good and great 3PLs lies in their ability to prevent errors rather than just catch them after they occur. Quality-focused 3PL WMS platforms embed automated verification checkpoints throughout the workflow, making it nearly impossible for incorrect items to reach customers while maintaining operational speed.

Automated error prevention throughout the process

✔ Implement automated pre-pick quality checks that verify order completeness and accuracy through automated validation, check inventory availability in real-time with automated alerts, and flag special handling requirements using automated business rules. These proactive measures prevent issues before they enter the fulfillment process.

✔ During the picking process, mandatory barcode scanning for each item, along with system-directed task assignment, ensures accuracy at every step. Automated system verification prevents workers from moving to the next pick until the current item is confirmed correct through the scan-match-scan process. Real-time inventory updates with automated exception handling maintain accuracy across all systems simultaneously.

✔ Lot tracking and expiration date validation provide automated compliance with regulatory requirements, while pick-to-light integration delivers 30-50% productivity improvements in automated pick and pack operations. These technologies work together to create multiple layers of error prevention.

✔ Post-pick automated quality checks include weight verification against expected totals with automated alerts for discrepancies, visual inspection for damage with automated photo documentation capability, and intelligent cartonization algorithms for automated optimal packaging selection. Final compliance validation encompasses automated FDA lot tracking and GS1 labeling, ensuring adherence to all regulatory requirements.

How cold chain WMS technology enables food recall prevention.

Performance monitoring and continuous improvement

✔ Track order accuracy by picker and shift with real-time dashboard updates that enable immediate coaching and process adjustments. Pick rate monitoring, combined with automated productivity benchmarking, identifies top performers and improvement opportunities. Meanwhile, order processing time tracking targets sub-24-hour fulfillment capabilities.

✔ Monitor on-time-in-full (OTIF) delivery rates with carrier performance tracking to identify shipping optimization opportunities. Dock-to-stock processing time measurement for inbound efficiency helps optimize receiving operations, while client-specific KPIs, including automated billing validation and audit trails, ensure accurate invoicing and client satisfaction. Learn how to calculate OTIF

✔ Implement weekly performance reviews using AI-powered demand forecasting and pattern identification for trend analysis. Provide individual coaching opportunities based on system-captured performance data, and generate process improvement recommendations from automated analytics that guide operational optimization.

✔ Monthly strategic analysis should include client satisfaction scores with automated reporting and SLA compliance tracking, as well as cost per order analysis with detailed labor time and material consumption tracking. Additionally, it should encompass technology ROI measurement, including automation impact and productivity gains.

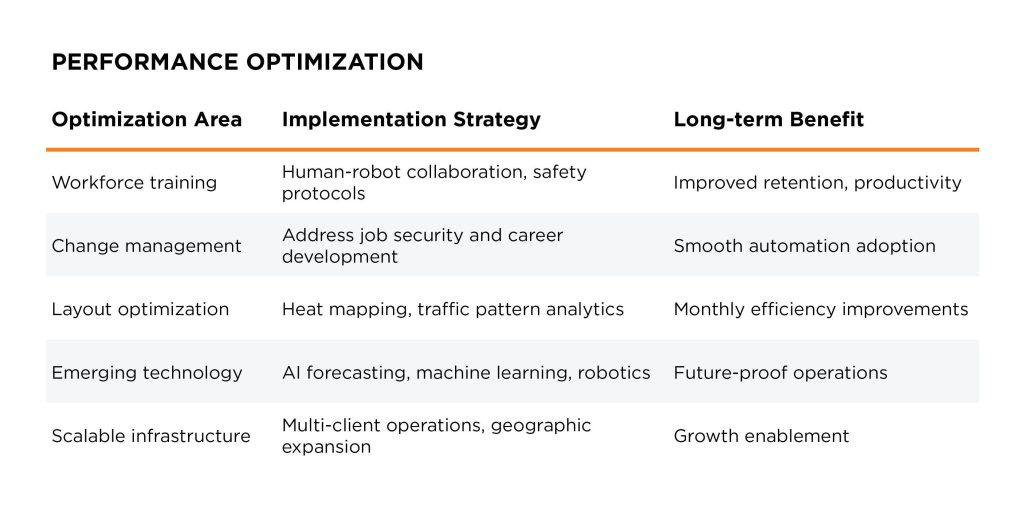

Performance areas and benefits

Top-performing 3PLs understand that optimization is an ongoing process, not a one-time project—but most lack the data visibility to identify improvement opportunities quickly. A sophisticated 3PL WMS provides real-time analytics and trend identification, enabling proactive optimization before performance issues impact client satisfaction.

Top-performing 3PLs understand that optimization is an ongoing process, not a one-time project—but most lack the data visibility to identify improvement opportunities quickly. A sophisticated 3PL WMS provides real-time analytics and trend identification, enabling proactive optimization before performance issues impact client satisfaction.

Workforce integration and training for automation

Design workflows where automation handles repetitive tasks while workers focus on complex decision-making and exception handling. Implement comprehensive safety protocols, ensuring workers feel comfortable operating alongside automated systems, and creating clear communication channels between automated systems and human supervisors.

✔ Establish exception handling procedures for situations requiring human intervention, such as damaged products, special packaging requirements, or system malfunctions. Train workers on system operation covering both normal operations and troubleshooting procedures, providing safety certification for working with automated equipment and collision avoidance protocols.

✔ Implement performance monitoring education, helping workers understand productivity metrics and goals, enabling them to optimize their own performance. Provide continuous improvement training allowing the workers to identify optimization opportunities and contribute to operational excellence.

✔ Address change management proactively by involving key workers in 3PL automation planning and implementation phases. Communicate automation benefits clearly, addressing job security concerns and providing career development pathways showing advancement opportunities in automated environments.

Process refinement and client excellence

✔ Conduct monthly layout optimization reviews using heat mapping and traffic pattern analytics to identify bottlenecks and improvement opportunities. Implement seasonal workflow adjustments using rule-based allocation algorithms that automatically adapt to changing demand patterns.

✔ Plan technology upgrade paths, including robotics integration and API connectivity expansion to support future growth. Provide regular performance reporting with executive dashboards and KPI summaries that demonstrate value to clients, while implementing proactive communication protocols using automated exception alerts.

✔ Maintain continuous service level improvements through client-specific workflow configuration that adapts to unique requirements and preferences.

Future-proofing through advanced automation

✔ Prepare for emerging automation technologies, including AI-powered demand forecasting with predictive analytics for automated inventory optimization. Machine learning-driven route optimization and automated system-directed task assignment will continue to improve efficiency, while predictive maintenance systems for automated equipment prevent costly downtime.

✔ Advanced robotics API connectivity for platforms like Locus, 6 River Systems, and AutoStore will enable increasingly sophisticated automated pick and pack operations. Integrate sustainability initiatives, including eco-friendly packaging materials with intelligent cartonization, carbon footprint reduction programs through optimized carrier selection and routing, and waste minimization initiatives supported by real-time material consumption tracking.

✔ Plan for market expansion capabilities through multi-client operational flexibility with centralized control and location-level configuration. Scalable cloud architecture with elastic scaling during demand spikes automatically handles growth, while geographic expansion readiness through multi-location management and carrier zone optimization supports business growth.

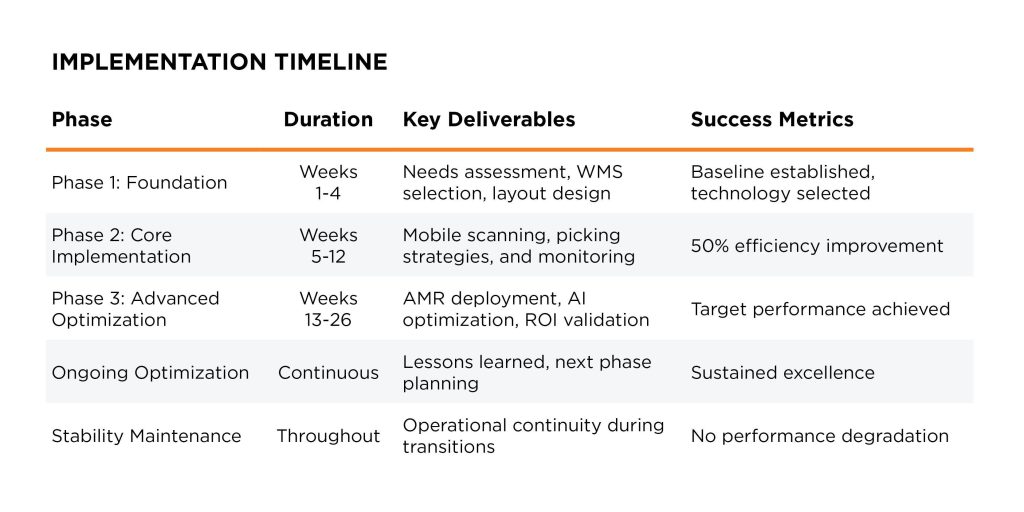

Timeline for implementing 3PL pick and pack

The most common implementation failure occurs when 3PLs try to change everything at once, overwhelming staff and degrading performance during the transition. A phased approach guided by your 3PL WMS partner ensures each improvement builds on the previous one, maintaining operational stability while steadily advancing toward excellence.

The most common implementation failure occurs when 3PLs try to change everything at once, overwhelming staff and degrading performance during the transition. A phased approach guided by your 3PL WMS partner ensures each improvement builds on the previous one, maintaining operational stability while steadily advancing toward excellence.

Need a hand? Book a personalized, strategic session with one of our 3PL WMS experts.

Phase 1: Foundation building (Weeks 1-4)

✔ Complete a comprehensive baseline measurement across all KPIs using real-time analytics dashboards to establish current performance levels. This data becomes crucial for measuring improvement and justifying investments in automation.

✔ Conduct a thorough needs assessment, including order volume analysis, product complexity evaluation, and automation readiness review. Evaluate current workforce capabilities, technology infrastructure, and operational bottlenecks to determine optimal automation strategies.

✔ Select a cloud-native 3PL WMS with proven automated picking integration capabilities and a sub-90-day implementation track record. Prioritize vendors that offer comprehensive automation support and have proven ROI in similar operations.

✔ Design optimized warehouse layout accommodating both current operations and planned automation systems. Plan infrastructure requirements, including power, networking, and space allocation for automated equipment.

✔ Begin planning for the integration of automation technologies, the connector ecosystem, and multi-carrier optimization. Conduct workforce readiness assessment and develop change management strategy for automation adoption.

Phase 2: Core implementation (Weeks 5-12)

✔ Deploy mobile scanning systems with automated lot tracking and compliance validation, enabling real-time inventory accuracy and regulatory compliance. Implement new picking strategies with automated system-directed task assignment that optimizes routes and reduces travel time.

✔ Begin automated quality control protocols with exception handling that prevents errors from reaching customers. Configure client-specific workflows and automated billing automation that ensures accurate invoicing and maintains client satisfaction.

✔ Launch performance monitoring dashboards with automated real-time analytics updating every few seconds, providing immediate visibility into operational performance. Optimize workflows based on AI-powered analytics and automated productivity benchmarking that identifies improvement opportunities.

✔ Expand successful implementations to additional operational areas with automated rule-based allocation algorithms. Begin robotics integration planning and automated API connectivity testing to prepare for advanced automation deployment.

Phase 3: Advanced optimization (Weeks 13-26)

✔ Deploy automation technologies, including AMRs and automated pick-to-light systems that deliver measurable productivity improvements. Implement AI-powered optimization with automated predictive demand forecasting to enhance inventory management and minimize stockouts.

✔ Launch client reporting systems with automated SLA compliance tracking that demonstrates value and maintains client satisfaction. Enable multi-carrier rate shopping and automated intelligent cartonization that optimizes shipping costs and packaging efficiency.

✔ Complete comprehensive performance analysis using automated KPI dashboards that track all critical metrics. Plan next phase improvements including advanced automated pick and pack robotics integration that supports continued growth.

✔ Document lessons learned and best practices with automated change management protocols. Validate 12-18 month ROI achievement through automation productivity and cost savings metrics, demonstrating clear value from your investment.

Success measurement and next steps

Key performance indicators

Track order accuracy rates targeting 99.9%, inventory accuracy targeting 99.5%, and customer complaint rates below 0.1%. Monitor efficiency metrics, including orders processed per hour with 30-40% improvement targets, pick rate improvement through automation, and order-to-ship time under 24 hours.

Measure financial performance, including cost per order reduction of 15-25%, technology ROI achievement targeting 250%+, and client retention rates above 95%.

Immediate implementation actions

This week:

✔ Assess your current 3PL pick and pack performance against the benchmarks in this guide

✔ Identify your three most significant operational gaps

✔ Begin the technology vendor evaluation process

30-day goals:

✔ Complete comprehensive needs assessment, including order volume analysis, product complexity evaluation, and automation readiness review.

✔ Select cloud-native 3PL WMS with proven automated picking integration capabilities and sub-90-day implementation track record.

✔ Design optimized warehouse layout accommodating both current operations and planned automation systems.

✔ Begin integration planning for automation technologies, 150+ connector ecosystem, and multi-carrier optimization.

✔ Conduct a workforce readiness assessment and develop a change management strategy for automation adoption.

90-day targets:

✔ Achieve 50% improvement in accuracy and efficiency metrics through automated workflows and intelligent task allocation.

✔ Complete comprehensive staff training on automated systems, safety protocols, and human-robot collaboration procedures.

✔ Launch automated client reporting with real-time billing validation and SLA compliance tracking.

✔ Validate initial ROI achievement through productivity gains, error reduction, and cost analysis.

✔ Implement the first phase of automated picking technology with measurable performance improvements.

Implementing this systematic 3PL pick and pack checklist today positions your 3PL business to dominate tomorrow’s marketplace. The 3PL market will grow by around 9% between 2022 and 2031, creating opportunities for you to deliver superior operational performance through automation.

The evidence surrounding automated 3PL pick and pack excellence demonstrates clear competitive advantages. It creates customer experiences that drive higher conversion rates, easier pricing justification, and sustainable competitive advantages that compound over time.