ERP vs. WMS software, head to head

Ever wonder what is the difference between inventory fulfillment in Enterprise Resource Planning (ERP) vs. dedicated WMS?

Too many companies are using their legacy ERP or WMS applications that can’t keep up with current demand – much less identify channels for new growth.

Today we’ll take these two inventory fulfillment systems head to head:

- What are their key differences,

- A little history on how each platform was built, and

- 4 reasons to stop managing inventory in your ERP and start growing with a modern WMS

So you can decide, ‘When is it time for modern WMS software?’

First, let’s define the two…

What is an ERP?

An Enterprise Resource Planning System is a huge category of accounting-first software, typically a suite of modular business applications that an organization can use to collect, store, manage, and interpret data. Inventory management in ERP is informative, but not directional or timely in terms of optimizing decisions in the warehouse.

An ERP reports inventory data as it relates to accounting, but lacks the efficiency and depth of logic that you get from a WMS.

It’s like building a robot to bring coffee to the office every day…

The ERP shows that someone ordered coffee, how much, its cost, and that it got delivered. But it won’t collect/interpret the day-to-day variables and direct the robot to better ways of getting the coffee out.

In a WMS, the insights look more like this:

“Someone in the office has a dairy allergy; bring some soy-based creamer. Don’t buy it from Supplier A because it’s on sale this week from Supplier B. That will save $3 per delivery. Put it into this type of package for the best quality. And take the stairs today because the elevator is out of service, and you won’t make it there on time”.

Having this functionality will become more impactful as you scale. So be sure to keep that in mind when evaluating what you want to achieve from your technology investment, both now and in the future.

Great as a business application

As a business application, ERPs are great for recording what happened, including financials such as profit and loss reports. The ERP vendor typically offers pre-built, modular applications that can be turned on to handle things like:

- Inventory management and fulfillment

- Supply chain management

- Material resource planning (MRP)

- Logistics and warehousing

- Sales and accounting

- Customer Relationship Management (CRM)

- Project management

- Human Resources, and more

ERPs give business units a common financial denominator to operate their business with an accounting-based view of their logistics, operations, finance, and inventory from a financial perspective.

Modules are interconnected within the platform so that various business units can share relevant data across platforms and automatically access information to calculate the profit margin of business decisions.

This may include things like the sales price, shipping, storage, and production cost of goods sold. It requires a person to analyze the data and still make decisions, versus the “GPS” showing staff the shortest, fastest, or cheapest way to manage inventory.

Inventory accounting vs. inventory management

Enterprise Resource Planning systems give CFOs data points to make high-level accounting and planning decisions. Most ERPs have inventory management system capabilities similar to WMS software but they still require a great deal of work. They’re reactive, versus proactive in how they guide warehouse staff.

For example, an ERP can provide information for items being received, picked, packed, and shipped. But these capabilities are designed heavily around accounting, order entry, and contact management—rather than streamlining your day-to-day warehouse operations within the context of the larger picture.

Dedicated WMS software systems

A modern WMS software system is a flexible, focused supply chain application that specifically tracks and optimizes materials/goods as they come in and out of the warehouse. Day-to-day inventory management activities happen on a deeper scale, with the key difference of providing automated insights and recommendations.

These WMS software capabilities are designed to continually optimize operational processes that directly impact external variables and the customer experience, vs. simple reporting for sales and accounting purposes.

How does a dedicated WMS handle inventory fulfillment?

Highly configurable with your ERP, dedicated WMS software systems extend best-practice warehouse management capabilities which most ERP applications can’t match. The modern architecture and flexibility of a true WMS become urgent requirements once the business hits a certain point in its growth journey.

Compared to ERP, a WMS brings a much higher degree of speed, efficiency, tracking, accuracy, and visibility across complex inventory fulfillment operations that have gotten out of hand. At a glance, the main differences between ERP vs. WMS include:

- Native RF device or scanning capabilities to remove paper-based work tasks in the warehouse

- Real-time visibility inside and outside the warehouse and +99% accuracy

- Support for multi-facility and multi-channel inventory management

- Pre-built, direct integrations with hundreds of supply chain applications, including existing ERP systems, eliminating custom setup and lengthy user onboarding

- Automated, system-directed pick-pack-ship focused on improving labor productivity, shipping, and customer experience

- Real-time views into merchandise entering the warehouse (including returns), being packed onto shelves and into various places, as well as when goods leave the warehouse

- Staff performance tracking and recommendations to improve how workers pick, pack, and ship orders; with KPIs tailored to the company’s unique workflows and customer needs

- Real-time system checks on product availability when a customer sends an order, without someone manually cross-checking the order and the stock, or having to manually enter a PO into another system

- Orders are automatically marked as ready for packing, virtually eliminating costly gaps between available-to-promise and available-to-sell inventory data

- Automatic syncing and foolproof workflows designed to significantly reduce overselling, chargebacks, excess inventory on shelves, shipping, and labor costs

Are there alternatives?

Yes, and here’s where the technology decision gets confusing. The options for inventory fulfillment and management are not black-and-white between ERP and WMS software.

You have: (1) ERP inventory management software, you have (2) modern WMS software (which can integrate with most ERPs), and then there’s this gray area in between… (3) legacy warehouse management or homegrown WMS bolt-on solutions.

WMS bolt-ons were an afterthought

To avoid investing in a full-featured WMS, companies often try embedding a WMS bolt-on product (often custom-built) within their existing ERP platform. The goal is to patch up the missing warehouse management pieces that were left out when the product was first built. But more often than not, it ends up costing much more in the long run.

Do you know why this deeper level of analysis and functionality didn’t make it into the ERP’s original roadmap? Most ERP vendors built their platforms in an era when nobody could fathom the terms: ecommerce marketplace, EDI, pick-to-light, system-directed put-away and returns, buy now pay later, buy now pick up (wherever)… and the list goes on.

ERPs and legacy warehouse management systems were created at a time when no one realized just how overwhelming it would become to manage omnichannel fulfillment with spreadsheets in an ERP.

It wasn’t until ecommerce and omnichannel exploded, and companies had to quickly re-architect their business processes to win over customers, did people start noticing the slippery slope that these band-aid solutions would create. However, for many companies, their ERP or WMS bolt-on remains the choice for inventory fulfillment.

ERP vs. WMS, which handles fulfillment better?

Every day we see companies that had purchased their ERP or legacy WMS system as a “silver bullet” without a clear picture of its long-term costs or limitations within the context of today’s disruptive supply chains. A lot of times, it’s not their fault.

When ERP is the only option

Sometimes, it seems like the ERP is the only option. It was probably a decent choice at the time. Maybe even the only choice, for several reasons:

- The company may have inherited the legacy system through a growth acquisition

- Their ERP was an expensive investment, and now the company believes an upgrade would be too long and costly of an IT project; “just make do with what you have.”

- ERPs keep Finance people happy, and someone in IT thought a WMS bolt-on embedded into the ERP platform would be quick and easy

- Oftentimes, the decision was made purely on not knowing what they didn’t know

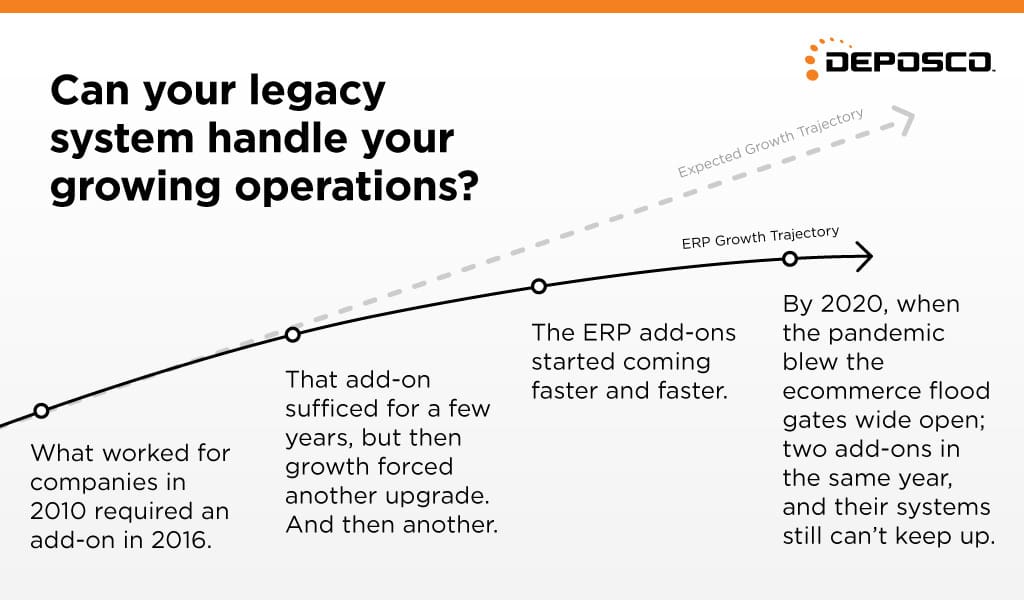

Can your legacy system handle your growing operations?

If you’ve ever sat in on meetings with an ERP sales team, you likely heard that warehouse inventory fulfillment is part of your ERP platform. Therefore, there’s no need to invest in a separate modern WMS.

Let’s unpack that for a minute.

Can your legacy system’s fulfillment capabilities handle the distinct warehouse management needs of your company? That depends on your unique business requirements, the extent of IT resources, and what value you are trying to get out of it long-term.

The cursory answer is “Yes”

Yes, ERPs do check the boxes on basic inventory fulfillment capability. They have to, to produce a balance sheet. When you dig deeper into the full picture, the real answer is “No; not if you expect to compete, remain relevant to the modern marketplace, and drive new growth year after year”.

Just ask any company that tried their ERP before coming to the expensive revelation that there is a huge difference between managing their growing fulfillment operations in an ERP vs. in a modern WMS.

The growth trajectory says “No”

Deposco gets calls every day from companies that learned the hard way; the “patchwork” approach to inventory fulfillment in ERP and legacy systems creates a slippery slope to growth:

Notice a pattern?

Each upgrade or ERP WMS system integration racks up higher and higher costs with the ERP vendor in consulting fees, middleware, and extra charges for going over the limit on transactions.

“What can we do to stop outgrowing this system?”

Ecommerce spending is predicted to hit $7 trillion by 2024, making up one-quarter of all global retail sales. Given the exponential growth the world is seeing in order volumes and complexities, conversations are quickly shifting from,

“What ERP WMS system integration can we develop next?”

to

“What can we do to stop outgrowing the functionality of this system?”

This growth underscores a very big difference between ERP and WMS systems in these 4 areas:

- Inventory visibility

- Manual vs. automated fulfillment

- Implementation, ease of use & adoption

- Direct integrations

All of these areas have a direct impact on long-term business value and growth. Learn when to buy a WMS – download the guide.

A dedicated WMS is essential for growth

To fully understand what is WMS and is it essential for growth, let’s deep dive into 4 key differences between ERP inventory fulfillment and modern warehouse management systems. Then you can decide: ERP vs. WMS, which is better for your business?

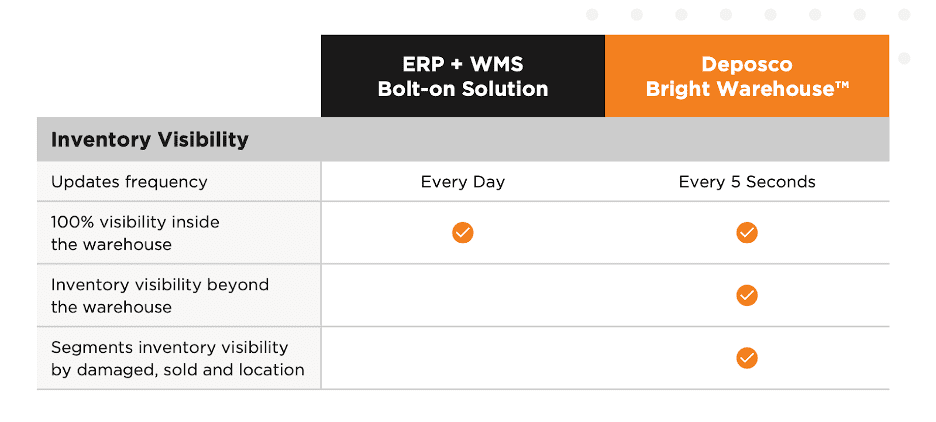

#1: Inventory visibility

In this age of widespread availability and adoption of cloud-based intelligence, it’s shocking that 69% of companies do not have total visibility over their supply chains. Inventory visibility should be one of your top priorities when comparing your inventory fulfillment software options.

The level of visibility differs greatly between ERP applications and WMS due to their very different architectures. Pay close attention to how, when, and why (for whom) was each product developed.

Inventory tracking, updating, and syncing ERPs were built at a time when supply chains were not so complex. Omnichannel fulfillment was not a thing like it is now. Consumers were okay with waiting 5+ days for delivery. Picking errors, rush shipping, and putting items on backorder didn’t put a brand out of business.

Omnichannel fulfillment and accounting don’t mix

Fast-forward a decade or so, and businesses are really feeling the negative consequences of an accounting-first design that was not truly architected for what goes on behind closed doors in an omnichannel fulfillment warehouse as we know it today.

Legacy ERP inventory management modules are reflective of inventory as they concern the CFO, accounting, and sales. Think of an ERP as “the memory”, whereas a modern WMS is “the mind”. They can track on-hand inventory but do not account for the full movement or traceability of it like a WMS.

- Latency: Even though ERP vendors built their fulfillment modules to “interconnect” with one another, they are slow and clunky compared to a WMS. Transactions do get updated as they occur, but in most ERP offerings, there is latency due to massive time delays between screens. Even just a one-hour delay in getting accurate information in the warehouse has acute consequences that will worsen as you scale. This lag is not consistent with the real-world activities in the warehouse.

- Reach: ERP inventory management systems are limited to tracking ONLY inventory within the warehouse’s 4 walls. Any tracking or syncing outside of that requires heavy manual work, phone calls and emails, and time to understand inventory existing elsewhere. In many cases, staff cannot trust what’s in the system on a day-to-day basis. Especially with the complexities of multichannel orders at play. The overhead is simply too much for humans to bear. And they shouldn’t have to.

With modern warehouse management software, users can instantly track inventory inside and outside of the warehouse. And trust that what is shown as ‘available’ in the system will match what’s actually on shelves, online, in another location, returned and on its way back to the warehouse, in a store, and ready to sell. With +99.95% accuracy:

- Inventory data updates to fulfillment teams in real-time

- Discrete-level inventory visibility control segments by damaged, sold, and location

- Cloud-native architecture vs. legacy interface

- Real-time visibility into fulfillment operations beyond the warehouse, including shipping carriers, marketplaces, EDI networks, and even customer-facing systems like billing

As you scale, having this level of real-time inventory visibility improves profitability and competitive advantage in all areas, including:

- Alignment between inventory available-to-sell & available-to-promise across channels

- Improved game-time decisions on the warehouse floor

- Significantly less risk of overselling, backorders & broken promises

- Operational efficiencies & fulfillment times under 24 hours

- Reduced labor & shipping costs for unlimited orders

- Optimal customer experiences leading to sales & revenue growth

#2: Manual vs. automated inventory fulfillment

Many ERP vendors tout automated inventory capabilities. However, one must look at the net story of how well the legacy system’s pick, pack, and ship capabilities can automate and optimize inventory, fulfill orders with ease and accuracy, improve labor management, and deliver flexible picking strategies.

Ask the vendor what the system can do well (and not well). How much manual vs. automated work does it take to get an order out exactly how your customer wants it, and how far can the system go as you scale?

What’s manual vs. automated in ERP?

Pick, pack, and ship fulfillment in an ERP or legacy system typically relies on a person to manage the build and release of pick waves to hand out to the team. This involves heavy manual work to extract data out of multiple systems into a spreadsheet, and then circulate that information (usually by paper) for fulfillment.

Unlike a WMS, ERP inventory management systems and bolt-ons focus their automation capabilities on order picking only, and the functionality is limited:

- The picking method is delivered via paper

- Not much scanning functionality at receiving; still requires much manual keying of data for inventory received

- One order at a time; no support for batch picking or pick lot control

- No advanced logic for shipping or route optimization

- No support for third-party integrations or customization

What’s manual vs. automated in WMS?

An advanced WMS uses scanners and modern logic to automate order picking, along with order receiving and returns; custom shipping needs; system directives based on order priority, and much more—all in real time, in a single system.

That means warehouse staff can see reliable stock levels in multiple locations and channels without spending hours on the phone, emailing back and forth, or walking the floor to check inventory. The warehouse automation component of a WMS ensures that orders can be fulfilled in a fraction of the time with virtually zero errors—typically within 24 hours of a customer’s click.

What automated tasks are possible in a WMS vs. ERP?

- Receiving, reverse logistics, returns, LPN batch picking with cartonization, and custom shipping via scanners in an integrated, paperless system

- Multiple orders picked at a time vs. just one

- 99% picking accuracy

- Multi-facility operations support:

- Pick lot controlled product

- Order splitting and routing at the line level (multi-line orders split into 2 shipments between warehouses)

- Single-unit ecommerce orders in bulk via scanner vs. paper

- Skip a pick and return later; no extra charge for automated waving and batching

- Pick-palletized inventory in bulk with system-directed putaway; rich scanning automation eliminates manual data entry in receiving and outbound fulfillment

- Pick to light automation

- Consolidation of same ship-to-address orders for picking

- Kit to order with pick waves

- Bulk pack multiple identical orders / multiple items

- Multiple packing stations based on order type or customer

- Direct APIs with shipping carriers; rate-shop outbound orders at packing or order import

- SSCC label generation and full EDI management

#3: Implementation, ease of use, modifications

One of the biggest differences between ERP vs. WMS purpose-built software happens during implementation (both initially and ongoing). Although, most companies don’t realize this until much later when they hit one or more of these breaking points:

- Order volumes get out of hand

- A new location(s), ecommerce marketplace, or sales channel such as a D2C is required

- Teams are spending too much time onboarding new hires and seasonal staff

- High turnover and shipping costs ignite that “Oh-$*%#!” moment

That’s when a company realizes that the time, cost, and learning curve to implement new functionality into their legacy system just can’t sustain the pace at which their needs are pulling them.

ERP inventory fulfillment, out of the box?

Inventory fulfillment solutions in an ERP are designed to implement “out of the box”. But what’s included in that box? Is the solution part of one big (rigid) product suite? Or a platform of modular, flexible supply chain software that can adapt to your changing needs?

Each ERP module requires a great deal of complexity, time, and cost to implement–usually 6 months or longer. Modules are not designed to work with other applications outside of their own.

The assumption is that the ERP applications will talk to other supply chain applications and work perfectly… and that all the costs associated with that initial implementation will cover everything you’ll ever need. [Spoiler alert: NOT true.]

A loose definition of “free”

Out-of-the-box ERP fulfillment functionality may work for smaller organizations where the volume of orders is low, there are fewer complexities in their supply chains, or they have tons of time/IT expertise on their hands. If you know you will not need much custom development work as your customers’ needs evolve, then the ERP’s fulfillment solution may suffice.

One must look deeper into the bundled licensed agreement to understand the additional needs and other modifications that will be required, to determine if the module is truly “free”.

What does your ERP’s fulfillment solution offer in the way of:

- Business strategy: reactive or proactive? Near- or long-term?

- Up-front design focus: business-centric or warehouse-centric?

- Scaling: do modifications require custom work with the vendor (or their consultants)? Or easy, pre-built APIs for third-party apps?

- Go-Live Time: 6+ months or as little as 55 days?

- Training and support: rollout + hand-over only, or the same team focused on your goals from implementation through all customizations, modifications, integrations, and upgrades?

ERP vendors only invest in new features about every 2+ years. They can’t possibly predict (and build in) all the functionality you’ll need until you are ready for the next big product release.

System modifications are not easy in any sense of the word. So they often get put on hold. In the meantime, you can expect stability problems, growing pains, missed opportunities, and a high risk of the system going down—usually at the worst possible moment.

Just think about the level of uncertainty and change we’ve seen in the past few years! Considering the total jump in ecommerce of 14.2%, this sheer growth in order volume is a perfect example of why you need a stable warehouse managing system with integrations that allow modifications much faster and easier.

WMS, scalable out of the box

If your company is growing fast and wants a complete understanding of all hidden costs, time to value, adaptability, and a clear idea of total cost over time, a modern WMS that integrates with your ERP is the best choice. These solutions focus on scalability and flexibility from the ground up, versus a product suite that boxes you into the common needs of companies “like” yours.

A focus on long-term business value during the design process is a hallmark of modern WMS software. A tremendous amount of expertise goes into the up-front design to ensure that the WMS solution will be:

- Easy to learn, during initial rollout as well as future capability upgrades, with new-user onboarding in under 15 minutes

- Free of problems with system stability, interoperability, and security

- Configured to your specific goals and processes, rather than force-fitting your business into the vendor’s pre-defined functionality

- Focused on results, market responsiveness, continuous improvement, and scaling without extra fees

What to look for during a WMS system evaluation

A good sign that the platform is truly “out of the box” is if the vendor can provide ALL of the following before starting your project:

- A detailed plan that models your unique operations

- Demonstrated knowledge of interoperability with existing applications, including your ERP and third-party supply chain applications

- Warehouse management metrics and KPIs tied to your unique customers’ needs

- Access to in-house expertise and existing tech partnerships (not third-party consultants) included in the contract

- Success stories with metrics specific to your challenges

- Detailed ROI calculations of ALL costs, including a clear maintenance, support, and upgrade process with no surprises

- Names and contact information for the implementation team, who will be the same team you work with always

When you’re ready to actively begin your WMS software comparison, here’s a free RFP template on what to ask in your evaluation.

#4: Direct ERP WMS system integrations

Enterprise Resource Planning systems do not offer the direct supply chain WMS software integrations required by today’s complex, competitive omnichannel space. As a result, you can expect increased costs and decreased flexibility to market changes.

Unanticipated costs of ERP vs. WMS

Changes can and often do lead to unanticipated costs as high as 3-4 times what was originally budgeted. The ERP vendor typically outsources the work to a third party and the fees are outside of the scope of your original contract.

This is a big problem, given the accelerating risk, time, and pressure on IT to get new functionality in place and get users onboarded.

For example, at some point many businesses will need to launch a new sales channel, such as a DTC ecommerce channel; add new locations, trading partners, applications, or services; or simply get a handle on increasing volumes that are draining their resources.

External systems and customizations

Legacy ERP inventory fulfillment applications do not integrate easily into external systems—like ecommerce marketplaces, shipping carriers, EDI networks, or billing systems—without expensive custom integration work or middleware. WMS does this as a standalone solution.

Cloud-based WMS software is built on flexible, modern technology that was meant from Day 1 to add what you need when you need it.

These systems include 100+ pre-built direct supply chain integrations, or sockets, which allow you to adapt the system to work how you need, versus the rigid functionality as pre-defined by your ERP vendor. Sockets allow quick customizations that make it easy to roll out new capabilities without custom coding or long and expensive consulting every time you need a change.

Benefits of modern WMS

The true difference between ERP vs. modern WMS is the long-term benefits to the business. An advanced WMS allows you to get a handle on near-term growing pains while driving exponential profitability year over year, including:

- Real-time visibility and total control over inventory including returns, both inside and outside of the warehouse walls

- Faster picking speeds and fulfillment in under 24 hours, consistently

- Lower logistics costs including labor and shipping

- 90-day implementation and onboarding in 15 minutes for new hires

- System reliability, data integrity, and security

- Reduced backorders, chargebacks, stock-outs, and labor turnover

- Analytics and performance metrics to support continuous improvement

- A quick, easy upgrade path to advanced order management capabilities, like intelligent order routing, drop shipping, segmentation, pre-selling, and more

- Seamlessly and fully connect physical stores when you are ready

- Ability to quickly fix new challenges, improve business processes, and grow market share

What is the ROI of WMS?

According to Forbes, many WMS services end up paying for themselves when used effectively.

The ROI of WMS comes from a variety of areas, including operational throughput and revenue creation to larger operational margins, 99.9+% order accuracy, employee retention, and better customer experiences. These solutions can be implemented in less than 90 days, with results in less than one year.

What can you save with WMS software?

Use this handy WMS Savings Calculator now!

Deposco has an extensive portfolio of customer success stories and videos across retail, ecommerce, and third-party logistics (3PL) businesses that implemented Deposco’s Bright Warehouse WMS platform. You can view more success stories here, or check out some highlights showing the ROI of WMS software below:

In conclusion

Legacy WMS and ERP inventory fulfillment applications can solve near-term inventory management problems but tend to ignore the larger picture. If your business is growing at a rapid rate, adding a modern warehouse management system to your ERP is the best choice for long-term business value creation.

The ERP trust-fall

Are you doing a “trust fall” by managing inventory in your ERP? What’s your level of trust…

- TRUST that your team will be able to process, pick, pack, and ship an accelerating number of orders per hour, with virtually zero mistakes or growing pains?

- TRUST to collect and sync real-time inventory data that will lead to profit-driving decisions?

- TRUST in real-time dashboards and recommendations for using your time wiser, improving what you do over time—rather than putting out fires and apologizing to customers all day, every day?

- TRUST that the system was built with your adaptability in mind first, with a process to proactively collaborate with you in a way that matches your strategic growth plan (not theirs)–and no surprise charges for it?

Maybe it’s time to evaluate a dedicated, modern WMS software that was specifically designed for modern-day ecommerce and omnichannel selling? It makes all the difference in whether your company is just “executing” inventory orders or really growing.

Who is Deposco?

Deposco is how fast-growing businesses rapidly scale their supply chain fulfillment operations. So they can see what inventory they’ve got, where it is, and where to position it to fulfill demand when It’s Grow Time.

It’s the only solution that provides this much actionable insight into both your supply chain and the broader marketplace. Streamlined into One Solution, One Focus, One Team. #ItsGrowTime

About Deposco

Deposco Bright Warehouse is the essential warehouse management system used by leading businesses to meet the intense on-demand sourcing and fulfillment requirements of today’s multichannel, omnichannel, B2B retail, and direct-to-consumer environments.

Bright Warehouse WMS prepares businesses to rapidly scale and support long-term growth including the addition of new locations, peak seasons, promotions, and new product launches—through the smartest orchestration of their building, hardware, inventory, and human assets.