A modern warehouse management system (WMS) plays a pivotal role in digitisation, which PwC says is what makes the supply chain more efficient, agile, and customer-focused1.

Building your WMS warehouse provides a real-time view of your entire inventory network, optimising fulfilment from click to order delivery.

Companies that use a WMS with integrated order processing can reap a 25% increase in productivity, a 20% gain in space usage, and a 30% improvement in stock use efficiency on average2. Furthermore, G2 predicted that 89% of organisations use modern WMS system functionality for labour planning and management3.

What is a warehouse management system?

A WMS system is a modern, purpose-built cloud platform that optimises every pick, pack, and ship decision to ensure your business makes the best use of its inventory. A warehouse management system solves the growing challenge of how to get more orders to the right locations with confidence, speed, and virtually no mistakes – at a lower cost.

Access our WMS Selection Center to Compare WMS Software Tools: Evaluation Checklist, RFP Template, WMS Savings Calculator, and more.

Ready to see our WMS in action? Ask for a demo today.

How a WMS system works

WMS systems make your inventory data fully transparent and accessible to all the players involved in fulfiling an order:

- Empower staff to choose the fastest, cheapest pick, pack, and ship method on every order

- Easily see what inventory is available and where it is at all times

- AI-driven recommendations simplify decisions and unlock massive operational efficiencies

- Flexible technology architecture gives you the freedom to add new features faster

- Sell more products in more creative ways

That includes best picking and packing strategies – such as batch, bulk, case/pallet, each, and cartonisation. Teams who are short on labour can easily prioritize orders, and even individual items as part of the order, with the ideal collection routes. And ensure all the necessary products ship on time, every time.

Intelligent order routing and inventory allocation can be configured to your specific warehouse management processes, which means more profits per square inch on the floor. With real-time data being fed into scanners, it’s very easy for staff to get orders out the door fast. And very hard to make a mistake.

Who uses WMS systems?

Businesses that struggle with the rising cost of out-of-stocks, overstocks, labour, and rapidly shifting customer preferences find rapid value from WMS software. It’s the smartest move to make for companies under pressure to deliver fast, flawless fulfilment experiences at optimal margins.

You can create massive efficiencies in storing, picking, packing, shipping, and moving inventory, alleviating labour problems while saving loads of money.

Read more: Customers using Deposco’s WMS have seen a +63% increase in top-line growth and a 150% increase in fulfilment efficiency alongside +99% order and inventory accuracy.

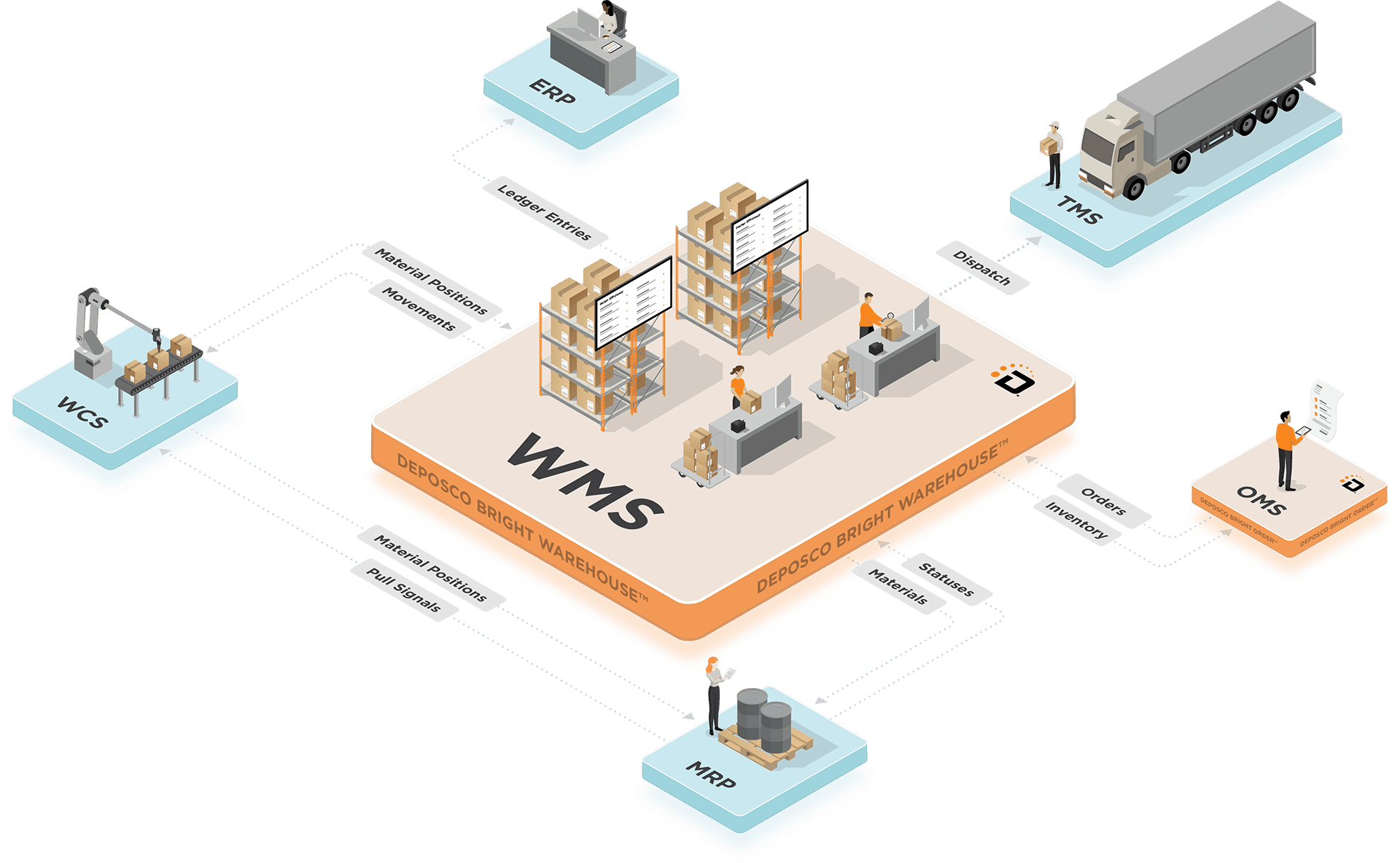

Types of WMS

When it comes to understanding all the various types of WMS warehouse software for your company, you have many options. The acronyms start to look like Alphabet Soup:

- WMS – Warehouse Management System

- WCS – Warehouse Control System

- WES – Warehouse Execution System

- MRP – Warehouse Material Requirements Planning System

- ERP – Enterprise Resource Planning

- OMS – Order Management System

- TMS – Transportation Management System

The options and different categories can be confusing, and not all are created equally! Categories range from standalone WMS tools, modern OMS + WMS, and specialised 3PL WMS systems to monolithic best-in-breed supply chain platforms, ERP systems with bolt-on WMS functionality, and cloud-based or on-premise solutions.

Different warehouse software systems are designed to suit different business needs. Some focus more heavily on inventory fulfilment. Some focus on material handling. Some try to do everything. It’s important to understand what these WMS systems do well and not well – along with what you need and do not need (or at least not right away).

Some areas to dig into include:

- The levels of complexity – how easily can it be implemented and learned?

- Installation and licensing – what are the hidden costs?

- System stability – will it break when you add other warehouse managing systems?

- Support – was the WMS solution built or acquired? Does it continuously guide your growth or leave you to fend for yourself with expensive third parties?

- Architecture – what are the limitations and unanticipated costs of adding future functionality? Will you have to adapt your processes to fit the system (when it should be the other way around)?

Features and benefits of WMS systems

WMS features can slow or grow your business

Did you know that the warehouse order-picking process accounts for 50-55% of total warehouse operating costs? With labour so hard to recruit and retain, you may want to automate parts of your fulfilment operations to offset costs and safeguard against disruptions.

Automation is only one piece of it. What other capabilities will help you step up to the demands of modern commerce and grow in a way that legacy WMS systems never will? Learn the top 6 features of a WMS that your warehouse teams can’t live without.

8 benefits of WMS driving ROI

Your company’s ROI will depend on how the warehouse management system can flex with your needs and deliver benefits in 8 areas:

- Real-time inventory visibility

- Data analytics and reporting

- Labour management and warehouse automation

- Warehouse utilisation and intelligent routing

- Returns processing

- Security and IT manageability

- Supply chain software integrations

- Customer experience

Learn how these top 8 benefits of WMS improve the ROI of your project.

Cost reduction and ROI in WMS

56% of retailers say shipping cost is their most significant fulfilment challenge, according to an omnichannel and fulfilment benchmark report led by Retail TouchPoints and Deposco. Throw in inflation, labour, transportation and logistics challenges, and something must give.

What does not “give” are the consumer’s expectations for product availability. Fast, flawless delivery and buying options that evolve constantly are table stakes.

How do you save on costs when nothing less than a perfect omnichannel experience will do? Technology is the answer. Read how to reduce fulfilment costs with a WMS.

To invest or not to invest?

Is it even a question? There’s no time to appreciate the ROI of WMS better than Peak Season. Those January blues kick in and companies decide they never want to go through the disaster that they just experienced.

According to our Peak Season report, 92% of supply chain leaders agree that a WMS will prepare their warehouse operations to be more profitable during peak. Of this group, 70% are implementing a WMS now. It’s critical to understand both the short- and long-term ROI of warehouse management systems.

Not sure how to present the business case and get something in place before the next seasonal rush? It’s not too late: Understand the ROI of warehouse management systems.

Warehouse management best practices

Warehouse management systems accelerate your growth by removing costly blind spots in 7 key areas. Fixing these blind spots will open up huge and immediate profitability:

- Enterprise Visibility – Do I know how much inventory I have? Is it accurate?

- Inventory Management and Tracking – Do I know where my inventory is located?

- Real-Time Allocation – Do I know if my inventory has been allocated to an order?

- Labour Costs – How do I manage warehouse staff performance?

- Backorders – How do I eliminate backorders?

- Peak Demand – How do I handle seasonal spikes?

- Online Inventory – How do I show available-to-promise inventory on my website accurately?

Learn about these warehouse management best practices.

Establish the right metrics in WMS

Throughput, error rates, processing cost per unit, and labour efficiency are the top WMS metrics that will grow or slow your company. Standardising and monitoring your KPIs will quickly fix bottlenecks, performance gaps, and inaccurate data to improve warehouse space, resources, labour, and time.

Learn the best warehouse management metrics to track including examples.

Use analytics to create predictability

Customers want certainty and predictability when they order products. But what about the certainty of your financial future? With supply chain data analytics and reporting, you can have it.

While it seems that being in supply chain management is nothing but predictable, robust warehouse management systems have turned that around.

Learn how analytics and reporting create predictable supply chains.

What to avoid in a warehouse management system

No matter what method you use for warehouse management – be it a legacy WMS system, ERP built in 2003, spreadsheets, or something else – there’s one thing we can all agree on: Anything can go wrong in the warehouse at any given moment.

For years, we’ve asked our customers to imagine their worst warehouse management nightmares before Peak Season hits. Then we have a little fun with it. “Witch” scenarios give them the heebie-jeebies? And how does Deposco WMS protect margins for these customers and keep them growing?

Avoid these Worst warehouse management nightmares.

Integrations in WMS – Confidence through innovation

In today’s volatile supply chains, confidence is king. Are you putting new technologies on hold because old ones keep holding you back? Nonsense!

WMS software integrations in a modern platform give you access to ready-made connections to existing systems (ERP, CRM) and future ones you may need: shipping carriers, marketplaces, MHE, and TMS. That means you can significantly lower the cost, time, and technical resources to start seeing value from your investment.

Pro-tip: Some WMS companies consider integrations out of scope. Or they only invest in the bare necessities – for instance, ONLY the 1-2 most common shipping carriers. You need a lot more options! Don’t get surprised by fees added after the project is underway. Ensure your partner is committed to continuously investing in, maintaining, and expanding their integrations library every year.

Learn how warehouse managing integrations fast-track your supply chain.

Shopify and WMS

Are you selling on Shopify or thinking about starting? Shopify is a big part of the sales strategy for many businesses that want to take advantage of high-growth markets like DTC.

A Shopify and WMS integration will make sure that happens without:

- Connectivity problems

- Manual work to connect to your financial systems (ERP)

- Unexpected technology limitations in scaling to other channels

- Problems meeting the requirements of doing business with large retailers/B2B

- Connecting to physical stores later, if and when you want to

- Guesswork on what products to sell

- High churn and return rates

- Poor responsiveness to new consumer preferences, new suppliers, and new products or service

Is your fulfilment software world-class? If not, learn how an integrated OMS and WMS solution for Shopify provides super-simple Shopify order fulfilment. Plus, the world-class Shopify experiences your customers expect.

NetSuite and WMS

Inventory management in NetSuite’s ERP has become grueling in the age where volume and complexities have put warehouse teams in peak season mode every day, all year long.

NetSuite is NOT a warehouse management system!

Organisations have learned the painful lesson that pureplay supply chain applications in NetSuite can no longer keep up with current demand. Much less identify channels for new growth. A WMS with integrations for NetSuite lets you connect to your ERP and get warehouse management operations into the current decade – while building adaptability to future changes.

Read why your future depends on NetSuite WMS integrations.

If you’re a 3PL

Integrations within WMS systems help a 3PL grow by creating a tech-forward platform that helps win more business. Efficiencies through an automated 3PL billing process, fully transparent order tracking, and winning customer service increase your cash flow with an incredibly fast time-to-value.

Read how 3PL integrations differentiate your busy third-party logistics company.

Labour, ESG, and returns

Labour and WMS automation

It’s the worst-kept secret. Everyone’s got a labour problem.

68% of mid-market businesses are struggling to attract talent. To boot, warehouse worker salaries increased 38% in the last 5 years, according to the latest warehouse worker job outlook from Zippia.

Learn how modern warehouse management systems help you effectively tackle ongoing labour management challenges.

Customers aren’t just excited by creative delivery and next-/same-day shipping. They expect it. In response, companies are investing in these top 5 key WMS automation technologies:

- Mechanisation

- Robotics, wearables, and augmented reality (AR)

- Advanced order management and DOM

- Enterprise-grade AI

- Frictionless unified commerce – every sale, anywhere

The flexible architecture of a modern WMS paves the way for these technologies, meeting tough customer demands while achieving healthier margins.

Learn the 5 WMS automation technologies to do more with less.

WMS systems support your ESG efforts

ESG is requiring companies to rethink order fulfilment for sustainable logistics. In a recent DTC Market report, 33% of supply chain leaders said their top reason for investing in technology was to make their business operations more environmentally friendly.

Informed decision-making around environmental responsibility ranks high on the priority list for today’s choice consumer. How does your fulfilment solution support that?

Warehouse management systems have a new job description. Learn how a WMS can support your environmental efforts: Technology’s role in ESG.

Returns management in WMS

The logistical journey of retail returns is getting expensive! About $500 billion annually, to be exact. But the environmental impact of returns is also well worth examining.

Learn how managing returns with a WMS system can reduce the environmental cost of returns. Plus, some strategies to reduce costs in other areas like shipping, warehouse, transportation, and labour.

Learn more: Ecommerce returns: the environment also pays.

Buying a warehouse management system

How to buy a WMS

The “why” of implementing warehouse management systems is easy. HOW to buy a WMS is often where companies run into misconceptions, costly surprises, and often stalled growth.

Which WMS is best depends on what you want to get out of it. Most warehouse management solutions do a good job of fixing immediate problems. But, few are designed to adapt and get you where you want to be in 10 years with minimal cost or disruption.

Confusing options, misleading noise from salespeople, hidden costs and maintenance, and features you didn’t realise you would need later are common factors leading to regrets. Learn how to buy the best WMS software for your business.

When can I get value from WMS?

You just saw on LinkedIn that your competitor has a shiny, new warehouse management system. Does that spark a case of FOMO (fear of missing orders)? What they failed to post is how long the sales cycle and implementation took. Or that a painful middleware project was required. Or how long it took their staff to learn it. In any WMS search, your timing, need, and fit are everything.

For most growth-minded companies, when you get value is just as important as what the WMS can do. Learn why time-to-value is the top factor in your WMS decision.

What’s the cost of WMS?

The cost of WMS can range significantly in the industry. The size of your overall operation and your annual budget will likely have the biggest implications for your WMS costs.

Factors that impact WMS pricing

If you are running a single warehouse operation, you can expect to pay a higher per-warehouse cost for your WMS system, both cloud and on-premise.

WMS costs are typically broken down per month for the first year. Cloud WMS systems are typically cheaper than a perpetual license service. On the lowest end of the range will be a small WMS for a single location and single user, without the bells and whistles. On the high end would be a true enterprise-level WMS system that manages multiple sites and requires infrastructure improvements at each.

The partner matters (a lot)

In estimating the cost of WMS, it’s crucial to understand the end game of your engagement. Does the partner help you set goals outside of fixing problems? You can save significantly on total costs for your WMS by choosing a partner that offers white-glove support and baked-in scalability — such as pre-built integrations architected on a common codebase.

Your partner’s level of support hugely impacts WMS costs in cases where you’ll need to introduce new functionality later. Without it, upgrades will require additional systems, which may or may not work well with your WMS out of the gate.

If they didn’t build room for new capabilities from the ground up, expect long delays and much higher prices, including consultant fees, which will significantly increase as you outgrow your system.

Get help defining and prioritizing your journey

An end-to-end WMS+OMS platform-for-growth partner will clearly outline that journey for you upfront, lowering the overall business cost of WMS.

It’s best to seek out multiple bids based on specific needs. Features that you can designate as ‘must-have’ versus ‘like-to-have’ may make your selection process simpler and easier to keep in line with your overall budget.

Due diligence: rightsize your WMS

While there is security in the long-term incumbent, for smaller brands seeking accelerated growth, it can also mean that the partnership isn’t there. How can you make sure your partner is focused on YOUR success?

It’s a lesson borrowed from the Goldilocks story. Of the many options, many are too small. A few are too large, but a handful are just right. The details are important and rarely outlined in the brochure.

So what questions should you be asking yourself? Learn more: 6 Things WMS Companies Left Off Their Brochure.

WMS for Peak Season

Shopping for a warehouse management solution usually starts when a company suffers that January hangover. Over-indulged spending to make up for what was a complete trainwreck, despite you doing everything you could do to prevent:

- Excessive seasonal labour, overtime, and onboarding

- Rush shipping fees

- Chargebacks

- Stockouts

- Late, missed, and incorrect shipments

- Angry customers

- Angry supply chain partners

It doesn’t have to be that way ever again. Start early and you can attack peak season all year long. Here’s how to prevent peak season chaos.

Implementing a warehouse management system

When something’s too good to be true, it usually is. The promise of a 45-day or “self-directed” implementation sounds pretty wonderful – until you realise that not all WMS implementations are the same.

The most misunderstood and value-eroding facts about implementing WMS software are often left out of the sales conversation. Get the facts: Beware of the 45-day WMS platform implementation

Compare WMS software tools

All WMS companies tell you they do pretty much the same thing. They don’t.

Are you getting pressure from all directions to quickly implement a modern warehouse management system? We’ve seen too many decisions that yielded quick wins but failed to drive growth year after year.

Below are a few great tools to help you compare WMS options, ensure a productive evaluation, and grow smarter.

What WMS capabilities do you need?

Learn the requirements and intangibles to consider as you prioritise the functionality you need now (and may need later).

Prepare for your WMS RFP

What should you ask to make your WMS evaluation productive and avoid costly lessons? Download a free WMS proposal worksheet to be more productive with your shortlist.

Get the RFP Template

What can you save with a WMS?

Use our interactive WMS Savings Calculator to instantly estimate your annual savings specific to your company’s operations over the next few years.

Difference between ERP and WMS

Can’t get a handle on orders? Maybe it’s because your staff is busy bouncing between multiple systems, scouring through spreadsheets and papers, piecing together unreliable data points, and handling customer complaints – rather than moving on to the next order. Congrats; you’ve outgrown your ERP.

Supply chains are changing at a pace that’s officially out of control. Stop fighting back with an accounting-first system that can’t keep up. Learn the huge difference between inventory fulfilment in ERP vs. WMS.

Monolithic suites vs. WMS

In the early days of ecommerce, technology acquisition looked very different. Trying to simplify things, companies bought all their supply chain software from a big name. Over the years, the evolution of monolithic product suites has brought substantial risk to businesses seeking frictionless growth.

Learn why you should avoid the monolithic suites approach vs. WMS.

- Source: PwC, Industry 4.0: How digitization makes the supply chain more efficient, agile, and customer-focused

- Source: FinancesOnline, 97 Supply Chain Statistics You Must Know

- Source: G2, 50+ Warehouse Automation Statistics to Streamline Operations