Consumer demand continues to drive consistent growth for retail brands and 3PLs. NRF’s retail sales forecast for ecommerce growth was 7-9% last year. Brick and mortar continues to drive 70% of sales in the US, but that lion’s share is being eaten away steadily. Inventory accuracy (or lack thereof) is a major culprit of diminishing customer experiences and sales in stores.

Retailers that master warehouse-level retail inventory accuracy are transforming these challenges into strategic advantages their customers notice and reward.

Isolating channels creates fulfillment problems

Many firms still use different technologies for retail inventory vs. warehouse inventory. This leads to inventory sync issues that frustrate consumers when using BOPIS (buy online pick up in store) or BOSS (buy online ship from store) services. With an expectation driven by years of “two-day shipping,” getting a backorder or cancellation due to inaccurate Available-To-Promise (ATP) stock can quickly lose a customer forever.

Unified commerce is a hot strategy to improve inventory accuracy, as people realize that we must stop isolating retail and direct-to-consumer in how we deploy our supply chains.

Read how to synchronize inventory and satisfy customer expectations across all platforms.

Let’s consider some things that are driving the problem.

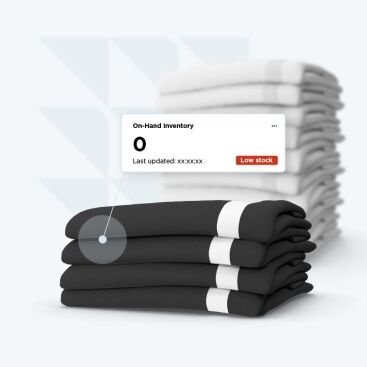

Store inventory is often out of control

Average inventory accuracy is about 65% in retail stores. This calculation is simply: “The Number of SKUs that are accurate divided by the Number of Total SKUs.” It doesn’t get into the degree to which they are inaccurate.

What’s going on? It’s complicated.

Customers complicate it. Industrial issues are easy to isolate because they are – generally – in-house people, process, and technology problems. Retail adds customers to the mix and you get some baked-in chaos.

Where even is the inventory?

Customers like to move things. Many customers treat the physical space like an online shopping cart. Thought about in Aisle 1, removed from “cart” in Aisle 10. This can be incredibly frustrating for apparel companies already dealing with finding the right size when pulling from the shelves.

You can’t be looking for your last Large jeans in the shoes section where they were discarded. And this is the mundane stuff; retail still records a 1.6% industry wide shrink number. Maybe it’s simply gone.

Where was it supposed to be?

Retail inventory systems can be very basic. Most classify inventory as back-of-house (BOH) and front-of-house. If you are lucky, BOH is run like a warehouse with clear locations. Often both are single zones with SKUs and quantities assigned to them. In a small shop, this is straightforward.

For years, major retailers with large square footage have taken this approach. While a planogram system managed facings, that data was isolated and only used for rotating products for marketing purposes. It was no help on a snipe hunt. Tribal knowledge ran the floor.

Are your fulfillment systems synced?

Many POS systems are isolated. A lot of systems are legacy technology that weren’t built for SaaS. In these setups, sales are often only reconciled at the end of the day. What happens when a big marketing sale causes a run on a product? Are you taking online orders for products flying off store shelves?

This can be a nightmare for BOSS, but it’s especially bad for BOPIS setups where someone thinks they are driving to pick up that item. They are inconvenienced online; they are inconsolable in person.

When did you last count?

Cycle counts are a common practice in the warehouse but not in brick-and-mortar retail. The average retail store does a single full inventory count every year. Oftentimes, it’s also done with an auditing firm for third-party validation. So the other 364 days a year, errors are slowly piling up and the delta between system and reality increases. You want to deliver fast-paced, high-demand orders, but how can you improve inventory accuracy with data well past shelf life?

Information you have on what’s in the store, and available, at any time, is often highly unreliable. That’s pretty troubling if you consider that the projected CAGR for BOPIS is 16.5% through 2032. Your customers want more of the thing that’s causing incredible headaches for your fulfillment promises.

Learn from the warehouse: inventory accuracy best practices

The average warehouse is expected to maintain at least a 90% inventory accuracy. Best-in-class dictates inventory accuracy should be 99.8%. Operations managers, particularly those in Inventory Control, are used to a process that demands near perfection.

Everything has a place in the warehouse

Every building has zones, aisles, racks, and discrete locations. Inventory is assigned to those locations and it’s only ever touched with a trackable transaction. Add, count, remove – all aided with scannable tracking to ensure human error is reduced to the absolute minimum. Nothing happens off-script.

Inventory harmonization isn’t optional

If you want to clear up your ATP issues quickly, synching the inventory is essential. The POS can’t be the system of record for retail inventory accuracy if you want your ecommerce to run smoothly. Using a single system is ideal, but ensuring that multiple systems are using an orchestration middleware is the next best thing. If your customers’ decisions ride on accurate, near real-time information, you have an obligation to provide it.

Adopt retail cycle counting

There’s no reason you aren’t doing this in an omnichannel world. In the same way that you will straighten the store before and after hours, it’s not a few more steps to run a sample cycle count while you are working the shelves. This simple maintenance can quickly close the gap between 65% accuracy in retail versus 90% in the warehouse. Better records, happier customers.

Treat all pockets of inventory the same way

Doing so brings a number of benefits:

- Same processes regardless of facility and format

- Data is maintained the same way regardless of the system

- Customers get a single view of your business regardless of channel

In the process, it’s important to address the technology element. Your best bet for improving inventory accuracy is an order management system (OMS) that considers all inventory in your network, helping you choose the optimal product to serve every order, every time.

See how Psycho Bunny uses Deposco to improve store inventory accuracy — Better yet, see how we’ll do it for you! Schedule a demo of Deposco today.