Welcome to the ultimate guide for executing order fulfillment! Explosive growth in ecommerce and omnichannel has forced many operational ‘blind spots’ on growth-oriented digital players. Forced to compete with order fulfillment powerhouses, these businesses struggle to deliver flawless omnichannel experiences that enable growth and scaling.

Bring your omnichannel journey into sharp focus. Today, let’s look into why omnichannel is non-negotiable, where you stand in the journey, and prescriptive ecommerce order fulfillment strategies and tools to illuminate a faster, smoother path there.

A clear reality

The biggest blind spot facing growing businesses lies in one clear truth: when it comes to order fulfillment, consumers now hold your brand to the same standards as the best experience available.

Blinders go up when you buy into the myth that ‘only large brands can do omnichannel right’. The reality is, great order fulfillment execution doesn’t require great budgets. All you need is a clear vision… a proven path to excellence.

Related: Curious about what is a modern WMS (warehouse management system)?

The brands you love to hate

When online consumer spending hit $791 billion in 2020, a 32.4% YOY jump, the stakes for supply chain management and execution also got higher. That was the biggest U.S. ecommerce growth in at least two decades.

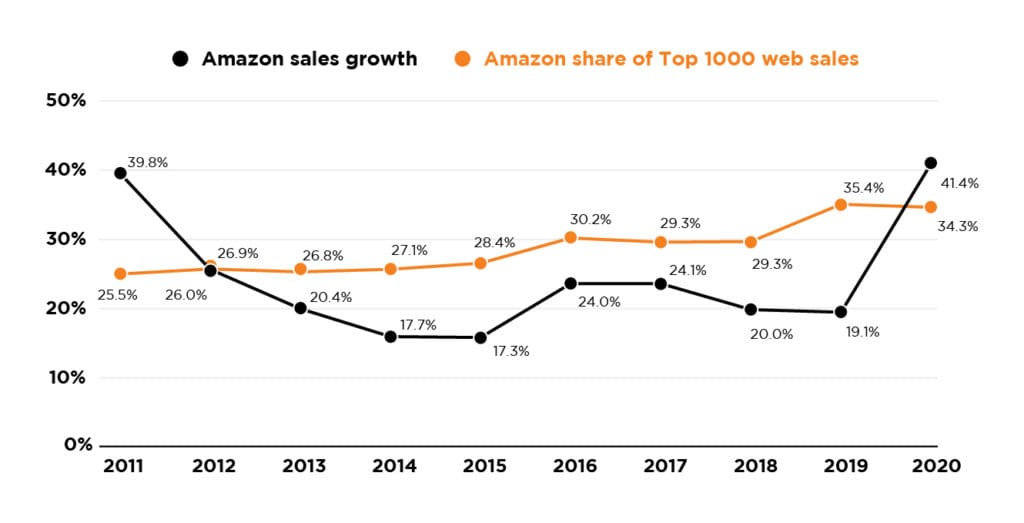

Amazon’s Disproportionate Share of Top 1000

Year-over-year growth, 2011-2020

In the chart above, there is no shock that Amazon represented 38.3% of all ecommerce spending in 2020 and nearly half (45.8%) of all U.S. online sales growth. But despite their lofty sales of $303 billion in 2020, Amazon’s share actually dropped, with 509 retailers on the Top 1000 having grown by over 25%.

Whether you love to hate them or hate to love them, these brands have mastered true omnichannel order fulfillment nirvana. You certainly don’t have their budgets, but these brands have lit a fire under your business to scale order fulfillment. And scale it fast, so you can get goods to match customer expectations—exactly when, where, and how they say so.

The good news is that given a clear path to omnichannel, businesses of any size can win.

Proximity to the customer defines great order fulfillment, not company size

It’s the experience and the perception customers get every time they interact with your company.

Let’s be honest; most businesses will never hit that $300 billion mark like Amazon. Nor will they ever fathom a budget like Bezos. So how did a once-startup retailer like Zappos pull off Amazon-like shopping experiences from nothing?

They created economies of connectivity. They built a foundation to continually deepen and improve what they know about customers. They’re using order fulfillment technology to get closer and closer to what makes them buy. And keep buying.

Insights over Inputs

These best-in-breed players reprogrammed the mindset from reactive, inventory-centric execution to fully mature order fulfillment, driven by customer insights.

Some of the best omnichannel businesses in the world are so agile with their insights that they can sell without even owning the inventory! They didn’t get there with a spreadsheet or a quick chat with the warehouse manager.

Your omnichannel strategy: crawling, walking, or running?

There are 3 stages of omnichannel maturity:

- Executing Inventory (warehouse management)

- Orchestrating Order Fulfillment (order management)

- Actioning Omnichannel Insights in Stores (connecting it all to store inventory)

Throughout our Growth Guides series, you’ll see that, as your company matures along each stage, the data you can measure and access will bring you closer to the customer and increase customer satisfaction, fueling long-term profitability.

Take a look at how technology nurtures this evolution from inputs to insights. Up first in this piece: EXECUTING INVENTORY.

I’m EXECUTING; now how do I orchestrate orders?

Executing Inventory is the most simplistic stage. Order fulfillment is a tactical, 1:1 “inventory first” process. Here, you have a broad-brush understanding of the customer. They buy; you then fulfill based on what you have. This phase is typically very manual or slow and reactive, with many blind spots. As long as a spreadsheet or warehouse manager says the product is there, you can make promises.

You’re exploring inputs like

- Do I know how much inventory I have? Is it accurate?

- Do I know where my inventory is located?

- Do I know if my inventory has been allocated to an order?

- How do I properly allocate my inventory for order fulfillment?

- How do I manage employee performance, and get better to save on labor?

- How do I eliminate backorders?

- How do I show available inventory on my website?

- How do I handle seasonal spikes?

But you’d LIKE to know things like

- What decisions should be manual?

- What decisions should be automated?

- How do I start drop-shipping?

- How do I make sure I have the right inventory represented by channel?

- How do I automatically route orders to speed and scale?

- Am I routing my orders properly?

- How do I enable pre-ordering?

First, get your warehouse in order

Ecommerce is receiving and fulfilling orders at an accelerating pace. Now is the time to build the foundation for what’s next—whether that’s supporting new locations, new channels, or simply increased volume. Whatever the case, your omnichannel experience begins in the warehouse.

Let’s look at why each of these questions is important at this stage, and some warehouse management strategies or tools that can remove blind spots right now:

Do I know how much inventory I have? Is it accurate?

Some things don’t scale. As order volumes grow, so does the impact of not properly representing on-hand inventory. This leads to backorders and/or overselling, higher costs, and frustration among your operations team. More orders mean more mistakes, slower execution, and less time to uncover cost-reduction opportunities—such as WMS rate shopping, which can reduce shipping costs by 2-20% in just a few clicks.

What to do

Trade-in “tribal knowledge” for a single source of truth that can keep pace with next-gen digital commerce. Warehouse management systems that integrate into order management software intelligently automate time-consuming, error-prone processes and deliver enterprise-grade benefits such as company-wide visibility, extensive flexibility, and real-time data generation.

These end-to-end WMS and OMS systems create fluid processes for your team and a fully traceable, unified view of all warehouse operations in one spot. They automate tasks in the cloud, like:

- Inbound/outbound tracking

- Streamlined waving, picking, packing, put-away and returns

- Advanced cartonization services

- Printing B2B retail-compliant labels

- Multimodal shipping management

- Centralized inventory knowledge across all warehouse activity

According to IndustryWeek, organizations that implement a warehouse management system report 4% higher perfect-order performance on average than those without these systems. In addition, companies have seen a 150% increase in fulfillment efficiency; +99.95% accuracy; and order fulfillment within 24 hours, on average, when using a WMS architected for order management.

Do I know where my inventory is located?

Why this matters

How much time do your associates spend tracking down inventory that’s in the wrong place? Or simply not there? What do manual processes in the warehouse cost your business?

G2 shared that order picking alone accounts for 50% of a warehouse’s labor costs. In addition, human error from manual processes is the #1 root cause of inventory fulfillment issues for 62% of respondents. These problems create more backorders, overselling, sub-optimal or poorly timed replenishments, higher on-hand inventory

and labor costs, and broken customer promises.

What to do

Employ an automated cycle count program that constantly audits your inventory for accuracy. Best-of-breed warehouse management solutions enable system-directed replenishments to confirm that inventory movement within the warehouse is done appropriately.

This dramatically improves productivity, while keeping everyone on the same page about what’s in stock, what’s needed, and how to proactively plan as order volumes rise.

Do I know if my inventory has been allocated to an order?

Why this matters

Without the proper representation of available-to-sell quantities, your warehouse can’t correctly prioritize, process, and ship orders. It’s a best guess as to whether an order will be backordered before being released to the warehouse team for order fulfillment. There’s no timely way to communicate backorders or fulfillment delays to your customers. They get mad, and you either lose the sale or compromise margins to make it happen.

What to do

Explore automated inventory allocation. Intelligent WMS + OMS systems use flexible rules to incorporate allocation into all customer orders needing to be fulfilled, including how to allocate, when to allocate, and in what priority. Rules consider inventory allocation in real-time when determining what’s available to sell. Some Ecommerce Order Fulfilment Software tools offer extensive order waving and batching capabilities that automatically allocate inventory to customer orders, and even consider order types and profiles.

This is especially useful with multiple sales channels that have detailed inventory allocation rules. Teams can easily prioritize what inventory within the warehouse gets allocated to what types of customer orders. Look for WMS systems that dictate not just what inventory is allocated, but where to allocate it, based on sales channel and factors that influence profitability, such as order fulfillment speed and operational costs.

How do I manage warehouse staff performance?

Why this matters

The highest operating cost in a warehouse is labor, which takes around 50-70% of the company’s warehousing budget. So YEAH… employee performance matters. As your omnichannel business grows, replacing blind, paper-based methods with a digital process to clearly evaluate warehouse staff performance will improve critical KPIs.

What to do

Make your labor investments count. Put a warehouse management system in place that can track and record all activity performed by users in the system. Warehouse and supply chain data analytics can then turn this information into reports and dashboards, so managers can easily track performance across the organization in a variety of ways, and deploy those resources optimally.

How do I eliminate backorders?

Why this matters

Don’t sell what you don’t have. That’s the fastest way to lose customers you’ve had for a long time.

Beyond the trust factor, there could be other items in the same order that are in stock, but the backorder causes you to lose the sale altogether. Or, the order may get split and shipped at different times, further inflating your costs. According to Multichannel Merchant, ecommerce backorders can cost $15-$20 each, eroding profits.

What to do

Simple, pre-built WMS integrations can significantly reduce backorders and overselling by connecting inventory data closer to the sale. These integrations or “sockets” ensure accurate inventory is in the warehouse management system at all times by publishing real-time Available-to-Sell data to sales channels.

Shopify is a great example. Without customization, you can set up Shopify to talk directly to your WMS or OMS system, so that when inventory adjustments are made, they get communicated back to sales channels on the fly.

How do I handle seasonal spikes in ecommerce order fulfillment?

Ecommerce is a game of seconds… especially as disruptions continue to threaten product availability. Salesforce expects logistics complications alone to result in $163 billion of added costs compared to peak season 2020. That means we can expect to see those dreaded words, “Out of Stock”, to trend well through the year and beyond. While there’s not much you can do to control industry-wide supply chain issues, you can get your warehouse organizationally primed for optimal order fulfillment all year long.

What to do

Explore a warehouse management system that enables your teams to process orders faster. Using advanced technology with system directives, validation, and warehouse processes, many warehouse management systems support system-directed put away, user-directed put away, and stock replenishments for different types of inventory based on volume or popularity.

Simple adjustments—like relocating complementary products next to each other, or stocking high-volume holiday products within arm’s reach of processing and packing

stations—can shave seconds, minutes, or even hours off your processing times. Even in smaller warehouses, those seconds add up to significant annual cost savings while improving daily throughput, sales, and profitability.

How do I show available-to-promise (ATP) inventory on my website?

Why this matters

‘Because Amazon does it’. True. More compellingly, it’s because that’s what omnichannel retail shoppers expect, and they could be more valuable than their non-digital counterparts:

Omnichannel shoppers have a 30% higher lifetime value than those who shop using only one channel. In fact, 51% of firms use at least 8 selling channels. The more you scale, the more selling channels you need to add. The more selling channels, the more logins/platforms accessing your website, leading to more data silos and a greater urgency for instant, accurate representation of inventory online.

What to do

If your online inventories are always off, it’s time to apply some science. Best-in-breed warehouse management software offers socket integrations that can automatically sync ATP inventory calculations to all sales channels. These integrations calculate ATP numbers as:

On Hand Inventory

– Allocated Inventory

– Unavailable Inventory (on hold/damaged/not pickable)

________________________________________________

Available to Promise

Streamlining your processes right now to allow real-time inventory tracking and data access in one system will cut a clearer path for growth later.

Congrats! You are Executing…

You know where your inventory is. Your warehouse associates are performing more efficiently. You’re making promises you can keep, and saving time and capital along the way. This is Step 1 on your path to scaling omnichannel order fulfillment. Need someone to turn on the spotlight?

Meet Deposco Bright Warehouse, the flexible WMS and OMS software platform used by leading businesses to meet the intense on-demand sourcing and purchasing as well as order fulfillment requirements of today’s multichannel, omnichannel, B2B retail, and direct-to-consumer environments.

With complete end-to-end control, automated inventory tasks, and enterprise-wide visibility, Bright Warehouse prepares businesses to rapidly scale and support long-term growth including the addition of new locations, peak seasons, promotions, and new product launches—through the smartest orchestration of their building, hardware, inventory, and human assets.

Up Next: What Does ORCHESTRATING ORDERS Look Like?

In the next Growth Guide, we will cover how to shift from simple execution of inventory to proactively orchestrating order fulfillment for complex, multi-location inventory management. Strategies will include things like:

- When do you know you’ve outgrown your ERP’s supply chain functionality?

- How to empower employees to review and validate orders for optimal decision-making?

- How to apply more advanced order management techniques like drop shipping, planning/ managing inventory by channel, automatic order routing and pre-ordering?

- Which insights and KPIs are vital to reaching the final stage of your omnichannel store?

About this series

Growth Guides is a series created to illuminate a smoother path to omnichannel mastery.

Offering prescriptive strategies at each stage of the growth journey, this series sheds light on what you should be doing right now to scale your journey faster, easier, and smarter.

Grab a printable version of this guide here or read the next edition, using the button below.