If you’re overseeing a 3PL fulfillment operation and feeling the pressure to plan for this year, you’re not alone. Many in the industry are preparing with the understanding that the complexities we’re all facing — economic shifts, geopolitical uncertainties, port strikes and potential trade wars, and evolving consumer habits — won’t vanish anytime soon.

During a recent IWLA webinar, Lauren Stemberger of Deposco and Macy Bergoon, SVP of Information Technology at Verst Logistics, dove into the realities ahead. The discussion was candid about the challenges and mindset shifts needed to thrive in an environment that’s only getting more complicated.

No silver bullet — Just speed to change

One recurring theme was the absence of a single “perfect 3PL solution.” As Macy put it, “We looked for a silver bullet to make fulfillment easy, but it doesn’t exist. It’s all about the speed at which you can implement and adapt.”

Are you trying to build an enterprise, but feeling the constraints of legacy processes and systems? Learn how Alogistico built a third-party logistics fulfillment platform they could commit to, roll out quickly, and not need to go back and change.

Instead of waiting for a magic feature or one-size-fits-all technology, the approach is to develop 3PL fulfillment software and processes that can flex when your customers’ requests or market conditions shift, which can happen almost overnight.

This mindset extends beyond static technology stacks. Lauren noted findings from a recent Industry Dive survey: “77% of supply chain leaders expect 2025 to be more challenging than previous years.” With that in mind, simply holding steady isn’t an option. Leaders must anticipate hurdles and keep flexible weapons at the ready, whether that’s adding a new 3PL integration module, revisiting operational workflows, or examining supplier relationships.

Own your peak season! See what our experts have to say and download your copy of the full report.

Standardization: The quiet hero

Macy emphasized that if the goal is agility, standardization is key: “We don’t implement solutions that aren’t scalable or standard. Doing something halfway now only means redoing it later when volumes spike.” That’s a tough lesson learned. By establishing standard processes and clear data rules before volumes surge, your 3PL can better avoid constant firefighting and last-minute patches.

This approach isn’t about playing it safe; it’s about setting a strong foundation. “We have to be ready to say yes to customer requests. But that means having options and smart 3PL WMS systems that can handle those requests quickly,” said Macy. When a customer calls asking for new carriers or different fulfillment options, having a standardized, scalable platform means you’re not starting from scratch each time.

Handling data deluge with clear KPIs

More data doesn’t automatically mean better decisions. During the webinar, both speakers touched on the importance of getting metrics right. “A KPI might mean one thing to an operations person and another to the customer,” Macy said.

He pointed out that what looks like strong on-time performance from one angle could be interpreted differently by a client who sees it through another lens, say customer satisfaction or returns management. That on-time delivery metric may be masking the order accuracy or packing issues because you are not looking at the downstream impact.

What do supply chain executives, operations, and planners care about most and how to measure them.

Ensuring everyone speaks the same data language—and understands what each metric really signifies—is crucial as we continue into 2025. Lauren reinforced this, noting that without consistent, standardized data, “You might have metrics that look great on paper, but don’t solve the root issues your customers care about.”

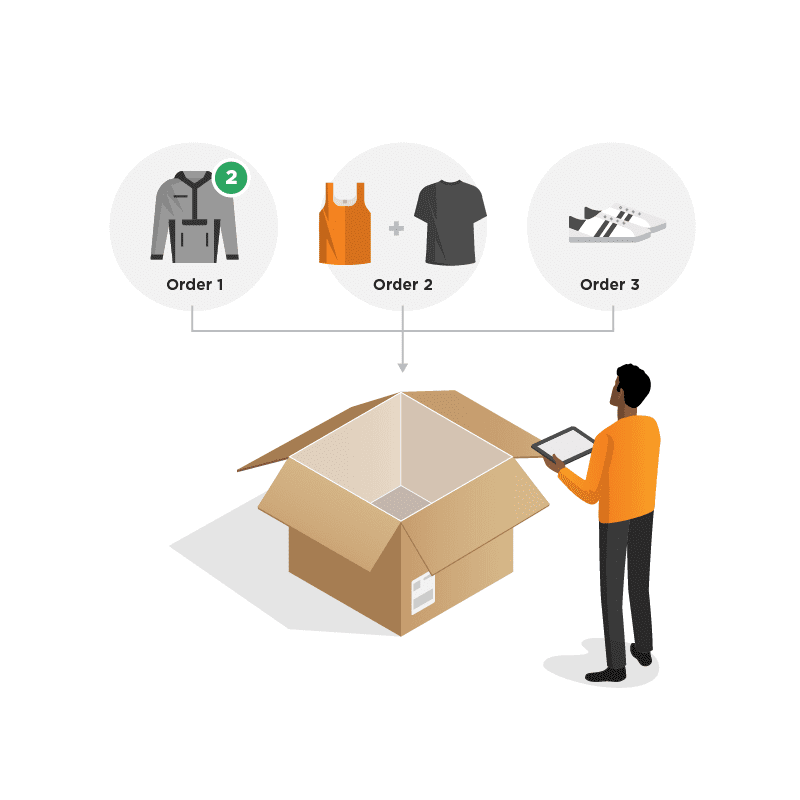

Flexibility in fulfillment and shipping

The conversation also underscored how important it is to adapt quickly to changes in shipping and fulfillment. Macy shared a recent scenario where Verst integrated a new parcel consolidation carrier just weeks before the holiday rush. “Normally, that’s a 30-45 day implementation,” he said, “but our customers needed cost savings and we had to move fast.”

What is consolidated shipping, why does it matter, and how does it help you ship multiple packages cheaper (and greener)?

That rapid pivot highlights the payoff of laying your groundwork early. If your systems and processes are flexible, you’re better equipped to say “yes” when these last-minute requests arise—and reap the rewards in customer satisfaction and cost savings.

People and culture: Don’t overlook the human element

While technology and processes dominated much of the talk, Macy and Lauren also acknowledged the importance of people. “Do we have the specialized talent to think through these problems?” Macy asked. It’s not just about the front-line associates picking and packing; it’s also about having analysts, IT specialists, and managers who can anticipate needs and troubleshoot issues before they become a crisis.

Investing in training, leadership development, and maintaining a positive culture might seem intangible compared to calculating lead times or inventory accuracy. Yet these are the elements that ensure your team can actually leverage the tools and workflows you put in place. After all, technology doesn’t run itself—people do.

Looking ahead, together

As we roll into the year, it’s clear that the conversation isn’t just about what technology to buy or which KPI to track. It’s about adjusting the entire organizational mindset and technical skillset to handle complexity gracefully. “We know the customers want it now,” Macy said. “It’s up to us to build the capability so that we can say yes more often than no.”

After Derby Supply Chain Solutions implemented Deposco to more easily manage diverse client needs, they saw 77% faster order processing times, 86% reduction in billing times, and new-client onboarding in two hours.

For those ready to roll up their sleeves, that future doesn’t have to be daunting. By embracing standardization, ensuring data consistency, investing in the right people, and staying agile, 3PLs can look ahead with preparedness and confidence—ready to respond to whatever changes come next.